Shanghai Optics is a leading manufacturer of custom Aspheric Lenses. We are experienced in achieving high precision quality Aspheric Lenses with different glass types such as CDGM, Hoya, Ohara, and Schott and materials such as Fused Silica, Germanium, Silicon, Zinc Selenide, Zinc Sulfide, Low-Temperature Optical Glass, and Optical Plastics. Whether your project requires low volume prototype production or high volume production, our engineers will work with you to ensure success. We specialize in different methods of Aspherical Lens manufacturing such as Grinding/Polishing, Diamond Turning and Precision/Injection Molding.

The optical engineers at Shanghai Optics showcase the manufacturing process of making the Aspheric Lens.

Single Point Diamond Turning (SPDT) Manufacturing at Shanghai Optics Inc.

Single point diamond turning is a mechanical machining technique using diamond tip tool bits which allows for the high precision manufacturing(producing) of off-axis parabolic mirrors (OAP), off-axis elliptical mirros(OAE) . At Shanghai Optics we use custom made state of the art diamond turning machines to produce spherical and aspheric lenses as well as off-axis parabolic, off-axis elliptical mirrors and planar surface optics.

Understanding the Single Point Diamond Turning Process

In single point diamond turning SPDT, a precision computer numerical control (CNC) lathe is fitted with a custom diamond tip which has has the ability to produce extremely fine, ultra precise cuts. Quality natural diamonds, prepared for the specific geometry of the lens desired, are used on our lathes. Electric motors and piezoelectric actuators, guided by computer-generated coordinates, are able to move the diamond tip with sub-micron accuracy. Each lens blank is first prepared using a series of CNC lathes with successively increasing precision, and is finally processed with the diamond-tipped lathe. This cutting tool produces sub-nanometer level surface finishes with sub-micrometer form accuracies that are far superior to the results of more traditional mechanical machining procedures.

Diamond turned optics are extremely smooth, require no polishing and have a high specular brightness. The diamond turning process is also repeatable and very deterministic, allowing for the manufacture of a series of batch consistent, identical, ultra-precise mirrors or lenses with almost no surface roughness. The process does require individual attention to each lens and careful monitoring of every stage of the process, and is practical only for small or medium-size runs. Diamond turning is suitable for many plastics, metals, glass and infrared materials. Silicon-based glass does not respond well to diamond turning techniques.

Quality Control in Diamond Turning

Quality control is essential for every stage of the SPDT process. Our state of the art metrology equipment, which includes profilometers, laser interferometers, and electron microscopes, allow us to ensure that every precision optical component in production achieves the appropriate form accuracy and quality of surface at every manufacturing stage.

Each of our diamond turned lenses are the fine product of extensive skilled labor combined with the best and newest optical technology and equipment. Since defective lenses cannot be re-polished but must be discarded, a careful attention to detail from the beginning of the SPDT process ensures we keep manufacturing costs as low as possible while maintaining the utmost quality and precision. There is no room for error in the diamond turning process, and even a tiny inaccuracy at any stage will result in a discard.

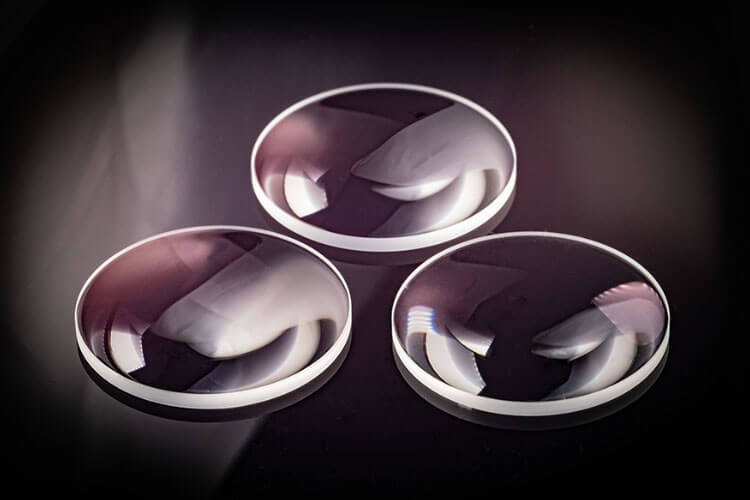

Precision Glass Molding is the process of producing high volume applications using an ultra-precision glass pressing process. It is used to manufacture lenses from consumer products such as camera and cell phones cameras to high end medical systems. In most high-volume applications, it’s more efficient and cost effective than traditional mechanical grinding and polishing procedures.

Glass Molding Process: Glass blanks are loaded into the molding tool. The process chamber is filled with Nitrogen to remove Oxygen from the working area. The system is heated using Infrared lamps to the working temperature. Once the transition temperature and glass softening temperature is reached, the molds will begin to close and press on the glass until the custom thickness is reached. When the molding is completed, the lens will be removed when cooled and the Nitrogen is removed from the system.

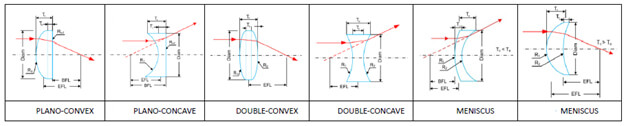

SHAPES: Plano-Convex, Plano-Concave, Double-Convex, Double Concave, Meniscus

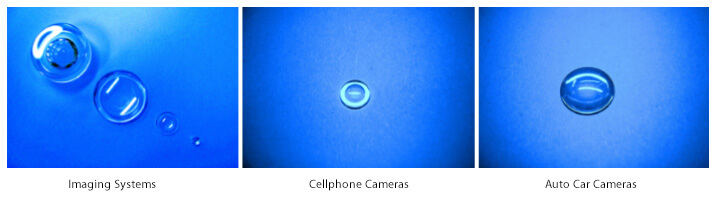

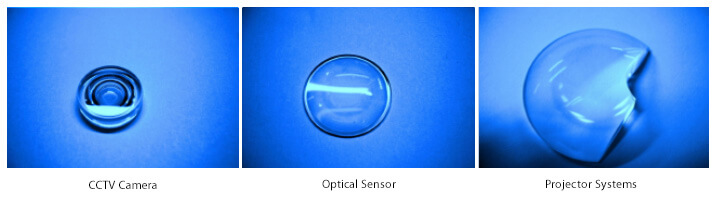

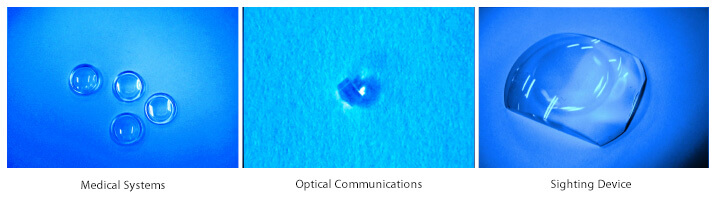

APPLICATIONS: Imaging Systems, Cellphone Camera, Auto Car Camera, CCTV Camera, Optical Sensor, Projection Systems, Medical Systems, Optical Communications, Sighting Device, Laser Collimator, Night Vision, LED Package

SPECIFICATIONS:

| Items | Concave and Convex | ||

|---|---|---|---|

| 0.6~5mm | 5~20mm | 20~60mm | |

| PV Value | 0.5um | 1.5um | TBD |

| Irregularity | <0.25 um | <0.25 um | <0.25 um |

| Roughness | 0.005um | 0.01um | 0.02um |

| Surface S/D | 40/10 | 40/20 | 80/40 |

| AR Coating | 0.50% | 0.70% | TBD |

| Centration | 60″ | 90″ | 120″ |

| Items | Double Concave | ||

|---|---|---|---|

| 0.6~5mm | 5~20mm | 20~60mm | |

| PV Value | 0.5um | 1.5um | TBD |

| Irregularity | <0.25 um | <0.25 um | <0.25 um |

| Roughness | 0.005um | 0.01um | 0.02um |

| Surface S/D | 40/10 | 40/20 | 80/40 |

| AR Coating | 0.50% | 0.70% | TBD |

| Centration | 60″ | 90″ | 120″ |

| Items | Double Convex | ||

|---|---|---|---|

| 0.6~5mm | 5~25mm | 25~65mm | |

| PV Value | 0.3um | 1.0um | TBD |

| Irregularity | <0.25 um | <0.25 um | <0.25 um |

| Roughness | 0.005um | 0.01um | 0.02um |

| Surface S/D | 40/10 | 40/20 | 80/40 |

| AR Coating | 0.50% | 0.70% | TBD |

| Centration | 60″ | 90″ | 120″ |

| Items | D-CUT Shaped | |

|---|---|---|

| 5~25mm | 25~65mm | |

| PV Value | 1.5um | TBD |

| Irregularity | <0.25 um | <0.25 um |

| Roughness | 0.01um | 0.02um |

| Surface S/D | 40/20 | 60/40 |

| AR Coating | 0.70% | TBD |

| Centration | 60″ | 90″ |

| Items | Special Shaped | |

|---|---|---|

| 5~20mm | 20~65mm | |

| PV Value | 1.5um | TBD |

| Irregularity | <0.25 um | <0.25 um |

| Roughness | 0.01um | 0.02um |

| Surface S/D | 40/20 | 60/40 |

| AR Coating | 0.70% | TBD |

| Centration | 60″ | 90″ |

The VeriFier XP uses the precision of phase modulation to show fine measurement detail on your parts with excellent accuracy and repeatability. ZYGO’s proprietary Metro Pro™ software offer a wide range of operational features and data analysis tools for unmatched measurement capability. Our trademark discounts for OEM-quantity orders are the best kept secret in the Photonics industry! Please contact our sales engineers for professional help for your cutting edge design with cost-effective solutions.