A high reflectivity mirror, also known as a supermirror, is a dielectric mirror that has been carefully designed to provide optimal reflectivity while minimizing any scatter and absorption effects. With reflectivity ranging from 99.8 to 99.999%, these precision laser mirrors are critical to laser beam steering, folding and interferometry. They have important applications in a wide range of fields ranging from security and defense to medical research and process control industries.

At Shanghai Optics we use state-of-the-art equipment to produce precision high reflectivity mirrors. Before they leave our factory, these mirrors are carefully tested to ensure they meet and exceed all relevant standards.

Our custom high reflectivity mirrors include both laser line mirrors, which reflect and redirect a narrow band of light centered on the laser line, and broad band mirrors which feature reflectance over a broad spectral range.

Both types of mirrors are dielectric mirrors, meaning they are composed of multiple thin layers of dielectric material. Ion beam sputtering is often used in the manufacture of these mirrors. High reflectivity at specified wavelengths is achieved by a combination of the right material, appropriate thickness, and a premium optical coating or coatings.

A laser mirror requires high laser damage thresholds, and we accomplish this with high quality fused silica substrates and a durable reflective coating that increases resistance to damage as well as enhancing the mirror’s reflective qualities.

Verifying the exact reflectivity of an ordinary mirror is done with spectrophotometry. Assuming scatter and absorption are insignificant, this device measures transmission and assumes that the intensity of the light is the sum total of reflection and transmission. Where reflectivity is less than 99.5 percent, this is a reasonable assumption; any loss of accuracy due to scatter and absorption is insignificant and can be considered noise.

This method, so easy to use with regular mirrors, no longer makes sense for super mirrors. Here the signal-to-noise ratio of spectrophotometer analysis becomes too great, and we need to consider the big picture. That is where cavity ring down spectroscopy comes in: a precise method of verifying the exact reflectivity of the highest reflectivity mirrors.

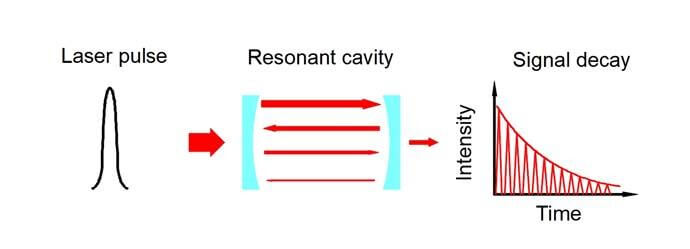

Cavity ring down spectroscopy (CRDS) works by means of a laser pulse, beamed into a resonant cavity that is bounded by two of the highly reflective mirrors being tested. A detector is placed after the second mirror. As the reflective laser light bounces about in the laser cavity light is lost with each reflection, and the total loss of each mirror can be measured by the decay time of the reflected light. This method treats equally all forms of light loss, including transmission, absorption, and scatter.

Our high reflectivity mirrors feature a combination super polished substrates and high surface quality in order to ensure optimal performance in even the most demanding applications.

Verifying the exact reflectance of every super mirror with CRDS spectroscopy is only one step in our quality control process. Our extensive in-house metrology equipment enables us to measure every aspect of each optical component that leaves our factory, from surface quality, flatness and absorption to polarization characteristics and laser damage threshold.

While we have a range of high performance super mirrors in stock, both with and without mirror mounts, we are also able to produce custom high reflectivity mirrors to fit your exact specifications. Contact us for manufacturing limit or custom specifications.

Factory Standards:

Shanghai Optics is able to produce custom high reflectivity mirrors to fit your exact specification requirements for many types of applications. Please contact us for design assistance or to discuss our manufacturing limitations.

Contact us today for assistance with your custom optics project.