Optical metrology stands as a formidable and adaptable tool utilizing light to measure object characteristics, finding applications across diverse fields. This article explores the mechanics of optical metrology, its multifaceted applications, and the merits and drawbacks of this extraordinary technology.

Operating by exploiting light properties for interaction with the object under scrutiny, optical metrology analyzes the reflected, refracted, transmitted, or absorbed light to extract vital measurements. Employing techniques such as interferometry, speckle pattern analysis, and laser-structured light pattern projection, optical metrology accurately gauges properties like distance, shape, and surface roughness.

Being a non-contact measurement technique, optical metrology minimizes the risk of damage to the object or part. It provides highly accurate measurements swiftly, making it valuable for applications requiring precision and speed. However, it is sensitive to environmental changes, making accurate measurements challenging in certain conditions. There may be limited range depending on the method used, hindering measurement of large objects. Additionally, the equipment can be expensive, limiting accessibility for some applications or industries.

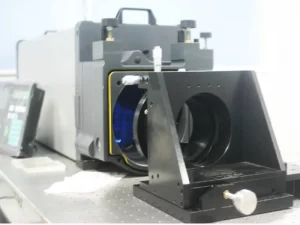

Zygo Interferometer

Precision Centering Machine

This measuring technology finds applications in various fields:

Shanghai Optics employs state-of-the-art metrology equipment, including the Zygo Verifire Interferometer and Trioptics MTF test stations, ensuring precise readings of surface accuracy and comprehensive infrared wavelength MTF measurements for high-precision lenses.

In conclusion, optical metrology, with its precision, non-contact nature, and speed, emerges as a valuable asset across industries. Its critical role in quality control, research, and development, coupled with advancing technology, solidifies its position as an indispensable tool for accurate and reliable data in various fields.