Powell lenses are specialized optics designed to transform laser beams into evenly illuminated lines, playing a critical role in various high-precision applications such as laser communication, medical equipment, and precision measurement systems. These lenses distribute light more uniformly than traditional cylindrical lenses, which often produce lines with bright central spots and uneven edges. The focus of this project is a custom-designed Powell lens featuring a 30° fan angle, optimized for a 2.5mm input beam diameter and wavelengths within the visible light spectrum.

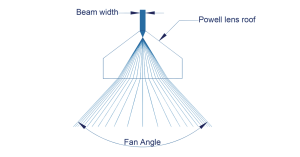

Unlike other lenses, Powell lenses have a unique prism-like structure with a rounded roof. This design allows them to convert a collimated, narrow laser beam into a straight line with uniform energy distribution. Cylindrical lenses tend to produce lines with fading edges and a bright center, but Powell lenses ensure the light spreads evenly, providing more consistent results across the entire line.

The design of a Powell lens is shaped by two key factors:

Fan Angle of Powell Prism

This specific lens is made from a material with a low refractive index, which enhances the uniformity of the light spot. The uniformity across the beam is excellent, with a variance of less than 10% over 80% of the beam’s coverage.

When designing a Powell lens for any application, several factors must be evaluated:

Custom Powell lenses, such as this 30° fan angle model, are essential for generating uniform laser lines in demanding applications. This particular design, optimized for a 2.5mm input beam and visible light wavelengths, showcases how crucial the fan angle and incident spot size are to achieving the desired performance. The lens’s low refractive index material ensures superior spot uniformity, making it ideal for a range of industrial and research uses.

Contact Shanghai Optics today! We’d be more than happy to discuss your projects and how to best bring them to fruition.