Case Study: Enhancing Indirect Ophthalmoscopes with Double Convex Lenses

Case Study: Enhancing Indirect Ophthalmoscopes with Double Convex Lenses

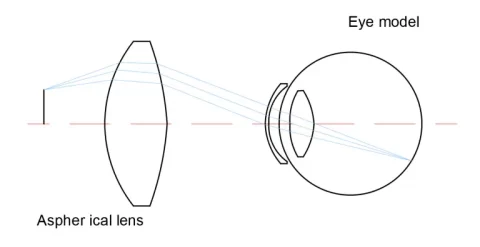

Indirect ophthalmoscopes are essential tools for eye examinations, combining a light source and an imaging system. These instruments use visible or infrared light to illuminate the eye’s fundus, capturing detailed images of its structure. By magnifying these images, doctors can better diagnose and monitor eye conditions.

Unlike direct ophthalmoscopes, indirect versions use a front lens held in front of the patient’s eye. The light reflected from the eye’s fundus passes through this front lens, forming an enlarged, inverted real image that is then processed by the imaging system.

The Role of Aspherical Lenses

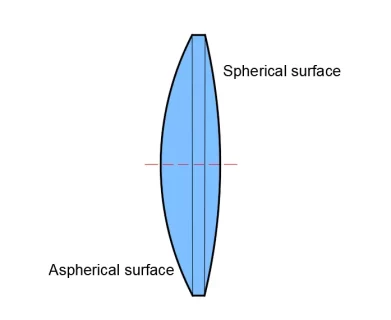

The use of spherical lenses in these devices often leads to suboptimal imaging. Therefore, aspherical lenses are preferred due to their ability to correct aberrations more effectively. High-order aspherical lenses, in particular, have multiple adjustable parameters to finely tune the lens curvature, significantly enhancing image sharpness and reducing distortion.

Lens Performance and Manufacturing

These lenses combine spherical and aspherical surfaces. Achieving high surface accuracy on aspherical surfaces, particularly with small vertex curvatures and steep slopes, is challenging. Surface error, measured as the PV (Peak-to-Valley) value, must be minimized to prevent image distortion and ensure clarity.

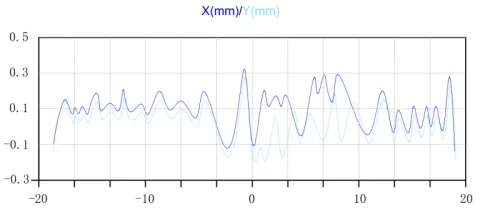

Using CNC aspherical machining, the lens undergoes a precise manufacturing process. The spherical surface is first machined and used as a reference for clamping. The convex aspherical surface requires an optimized polishing mold. Online detection during processing ensures that the lens meets stringent surface accuracy and quality standards, achieving a surface error PV of less than 0.5 micrometers and an eccentricity of less than 1 arcminute.

Additionally, the lens surface is coated with Vis-NIR broadband antireflection film, enhancing imaging quality and compatibility with infrared lighting.

The 40D high-order aspherical lens exemplifies the significant improvements in indirect ophthalmoscopes’ imaging capabilities. Through advanced design and meticulous manufacturing, these lenses correct higher-order aberrations, reduce distortion, and provide superior visual quality. The precise CNC machining techniques ensure minimal surface errors, while the Vis-NIR antireflection coating enhances clarity and adaptability to various lighting conditions.

The advancements in double convex lens technology, as highlighted in this case study, emphasize the critical role of high-quality optical components in delivering accurate and detailed ocular assessments, benefiting both healthcare providers and patients.

Contact Shanghai Optics today! We’d be more than happy to discuss your projects and how to best bring them to fruition.