Freeform Optics: Innovations in Custom Optical Design

Freeform Optics: Innovations in Custom Optical Design

Freeform optics represent a cutting-edge approach to optical design, enabling the creation of complex, non-symmetrical surfaces that precisely control light. These advanced optical components break away from the traditional symmetrical designs, offering a range of unique benefits tailored to modern applications.

What Are Freeform Optics?

Freeform optics are specialized optical components characterized by their non-rotationally symmetric and intricately shaped surfaces. Unlike conventional optics, which typically rely on simple, rotational symmetry, freeform optics are designed with complex surface geometries that allow for precise manipulation of light. These designs can be customized to meet specific needs, such as enhancing image quality, reducing aberrations, and improving the overall performance of optical systems.

Key Benefits of Freeform Optics

- Miniaturization and Weight Reduction: One of the primary advantages of freeform optics is their ability to consolidate multiple optical functions into a single component. This capability leads to the development of smaller, lighter devices, which is particularly beneficial in industries where space and weight are critical factors.

- Enhanced Optical Performance: Freeform lenses offer superior control over optical aberrations, resulting in clearer images, broader fields of view, and sharper focus. This makes them ideal for applications requiring high precision and accuracy.

- Customizable Designs for Specific Applications: The flexibility of freeform optics allows for the creation of components tailored to unique requirements, such as generating specific illumination patterns, controlling light distribution, or achieving non-standard image distortions. This adaptability opens up new possibilities for innovative optical solutions.

- Precision Alignment Features: The incorporation of specialized alignment features in freeform optics simplifies the manufacturing process, ensuring accurate surface measurements and seamless integration into optical systems.

Challenges and Techniques in Manufacturing Freeform Optics

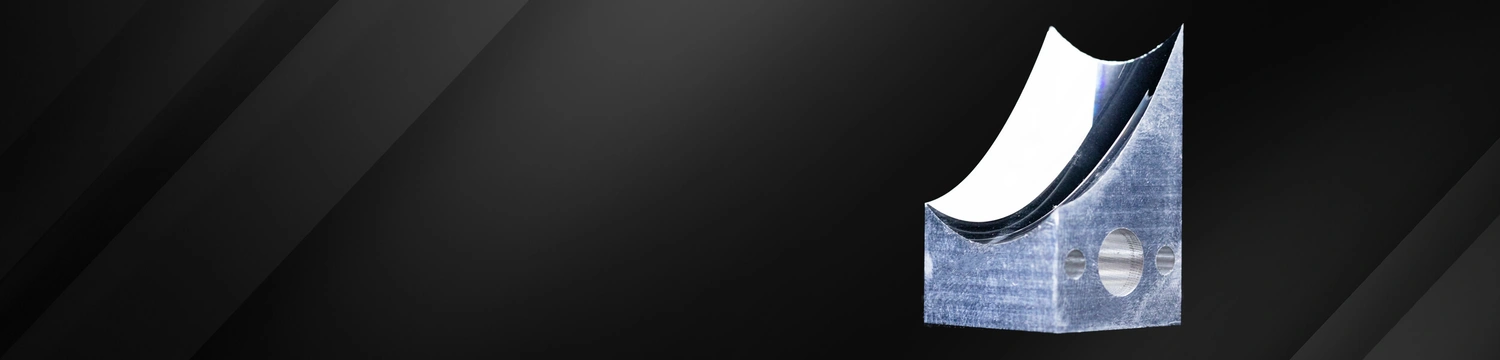

Producing freeform optics is inherently more challenging than manufacturing traditional optical components due to the complexity of their surfaces. Advanced techniques such as diamond turning, precision molding, 3D printing, and computer-controlled grinding and polishing are often employed to achieve the necessary precision. Even when molding is used, the initial mold templates are typically created through subtractive manufacturing processes to ensure accuracy.

Freeform Optics Production

Shanghai Optics is at the forefront of freeform optics manufacturing, utilizing state-of-the-art CNC machining and polishing techniques to create a wide range of optical components, including lenses, mirrors, and prisms. With extensive experience in precision molding, we supports high-volume production of freeform optics, ensuring that each component meets the rigorous standards required for cutting-edge applications.

From the initial design phase to final production and testing, Shanghai Optics provides comprehensive support throughout the entire optical development process. Whether your project involves standard spherical or aspherical elements, or you require custom freeform optics, our team is equipped to deliver high-quality solutions tailored to your specific needs.

Contact Shanghai Optics today! We’d be more than happy to discuss your projects and how to best bring them to fruition.