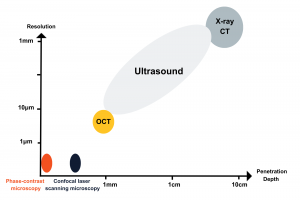

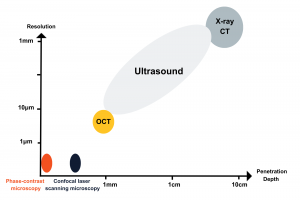

In various industries, non-destructive testing (NDT) is a critical practice for evaluating materials and structures without causing damage. Among the diverse NDT techniques, Optical Coherence Tomography (OCT) has emerged as a highly promising technology. Its superiority over traditional methods, such as ultrasound inspection, lies in its higher resolution, faster imaging, non-contact, non-invasive capabilities, and the ability to perform 3D imaging and dimensional analysis. This article delves into the applications of OCT in NDT, specifically focusing on its role in medical devices, displays and panels, and the aviation and automotive industries.

OCT Inspection for Non-Destructive Testing:

Utilizing infrared light, OCT provides surface profiles and information about subsurface structure and uniformity, delivering higher resolution and faster images compared to ultrasound inspection. This non-contact technology requires no coupling medium, ensuring accurate real-time information for in-situ process feedback and high-throughput quality control on finished parts.

Compatible Materials:

- All dielectric materials

- Paints, glasses, foils, coatings

- Polymers, silicone, rubber

- Plastics (to less depth, ~2 mm)

- Metals (surface features only)

Non-Destructive Testing

Advantages of OCT:

- High Resolution and Faster Imaging: OCT offers exceptional image resolution, ranging from 2.6 to 10.0 µm. This high resolution allows for the detection and characterization of the smallest defects within the inspected material, surpassing the capabilities of ultrasound inspection. Additionally, OCT provides faster imaging, enabling real-time or near-real-time inspection, thereby enhancing the efficiency of NDT processes, reducing inspection time, and improving overall productivity.

- Non-Contact and Non-Invasive Nature: A key advantage of OCT is its non-contact and non-invasive nature. Unlike traditional NDT techniques that often require physical contact, OCT utilizes light waves for imaging, ensuring the integrity of the inspected object remains intact and undisturbed. This characteristic is particularly beneficial when dealing with delicate or sensitive materials, making OCT an ideal choice for quality control and assurance.

- 3D Imaging and Dimensional Analysis: OCT’s ability to acquire three-dimensional images provides a comprehensive view of internal structures and defects within an object, enabling a thorough analysis of material integrity and dimensional characteristics. By capturing volumetric data, OCT allows for precise measurements, facilitating dimensional analysis and defect quantification. This capability is especially valuable in industries where accurate measurements are critical, such as aerospace and automotive manufacturing.

Applications of OCT in Non-Destructive Testing:

- Manufacturing: OCT proves to be an excellent tool for evaluating the shapes and dimensions of tools, molds, and final parts, including applications in polymer-based 3D printing. It provides real-time process feedback for controlling ablation depth during laser machining and detects defects while facilitating dimensional analysis in additive manufacturing.

- Medical Devices: OCT plays a crucial role in the inspection and quality control of medical devices, including micro optics and aspheres. It aids in assessing implantable devices, ensuring structural integrity and dimensional accuracy. Additionally, OCT facilitates the examination of biomaterials, detecting manufacturing defects or material inconsistencies related to medical optics.

- Aviation and Automotive: OCT is instrumental in the aviation and automotive sectors, aiding in the inspection of critical components like turbine blades, engine parts, and composite materials for structural abnormalities or hidden defects. Early detection of such issues enhances the safety and reliability of these vital systems.

- Displays and Panels: The display industry benefits significantly from OCT in NDT, enabling the evaluation of panels such as LCD and OLED screens. It ensures uniformity, pixel integrity, and absence of defects, utilizing high resolution and fast imaging capabilities to identify small imperfections or performance issues.

Optical Coherence Tomography (OCT) stands out as a powerful tool in non-destructive testing, surpassing traditional techniques like ultrasound inspection. Its high resolution, faster imaging, non-contact nature, and 3D imaging capabilities offer significant advantages across various industries. OCT finds applications in the evaluation of medical devices, displays and panels, as well as aviation and automotive manufacturing. With ongoing advancements in OCT technology, further improvements in NDT processes can be expected, ultimately enhancing quality control, product reliability, and safety standards across industries.

Do not hesitate to contact Shanghai Optics today. We’d be more than happy to discuss your projects and how best they can become a success.