Optical design is the process of studying application requirements and designing optical systems to meet specific needs of optical instruments. The entire system may include optics, light source, sensor, electronics boards, display device, and/or other components. The system performance is not totally dependent on the optics. Every component within the system has contributions to the overall performance of optical instruments.

For creating optical specifications and designing the optical components or assemblies, designers need to have a wide knowledge of opto-electronic components such as optical receivers and light sources, know the system performance limits, in-depth understand manufacturing tolerances and fabrication costs.

The Modulation Transfer Function (MTF) is an important tool to quantify the overall imaging performance of a system. MTF is a function of spatial frequency (v), which is generally in the form of line pairs per millimeter (lp/mm). Every component within the system has an associated modulation transfer function. This includes the imaging lens, sensor, electronic board, etc.

The cut-off frequency (v0) of a lens is given by

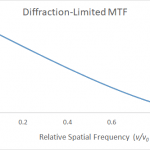

Where λ is the wavelength expressed in mm and f/# is the lens focal-ratio. An optical system cannot transmit information of spatial frequencies higher than the cutoff frequency. The diffraction-limited MTF is used to predict the upper performance limit of a lens system.

A simple formula can be used to calculate the diffraction-limited MTF of a lens with a circle pupil.

The diffraction-limited MTF curve is plotted.

As an example, a diffraction-limited lens with an f/# of 4 and a working wavelength of 0.55µm, the cut-off spatial frequency is approximately 454lp/mm and the MTF is approximately 0.50 at the spatial frequency of 1837 lp/mm.

• Manufacturing tolerances

An optical system cannot perform better than its diffraction-limited MTF. Manufacturing errors and internal-reflections of optical systems can decrease the MTF values. Typical manufacturing tolerances are listed in the following table.

| Parameter | Commercial | Precision | High Precision |

| Diameter | 0 – 0.1mm | 0 – 0.025mm | 0 – 0.01mm |

| Thickness | ± 0.1mm | ± 0.05mm | ± 0.01mm |

| Power | 3.0λ | 1.5λ | λ/2 |

| Irregularity | 1.0λ | λ/4 | λ/20 |

| Scratch – dig | 80-50 | 40-20 | 10-5 |

| Wedge | <5 arcmin | <3 arcmin | <1 arcmin |

| Reflection (AR coated Surface) | <1.5% | <0.5% | <0.2% |

Knowing the possible MTF curves and manufacturing tolerances can help optical designers more accurately predict the system performance and estimate fabrication costs of optical products.

Shanghai Optics has an experienced engineering team to bring customers the most feasible design at the fastest speed and most affordable cost. Shanghai Optics offers variety of services in lens design, research and production.

References: