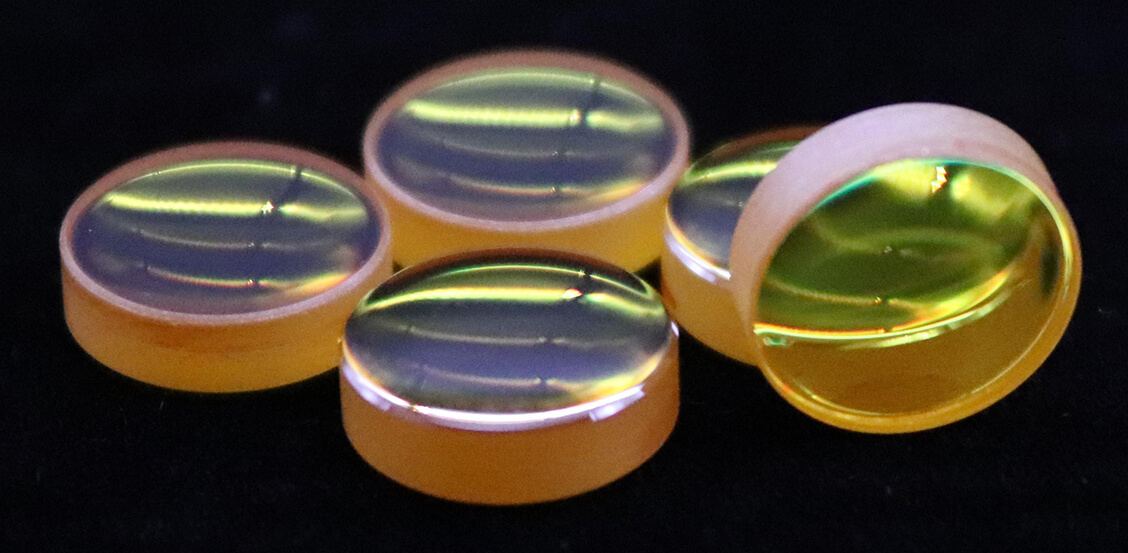

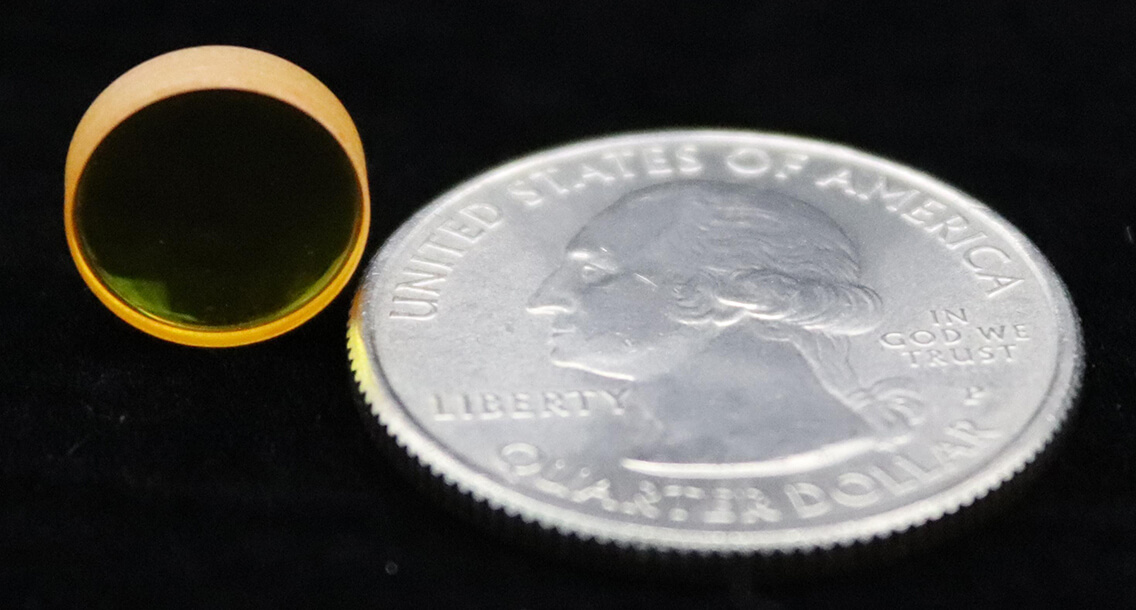

Zinc Selenide Aspheric Lenses – Diameter: 10mm / Thickness: 3mm

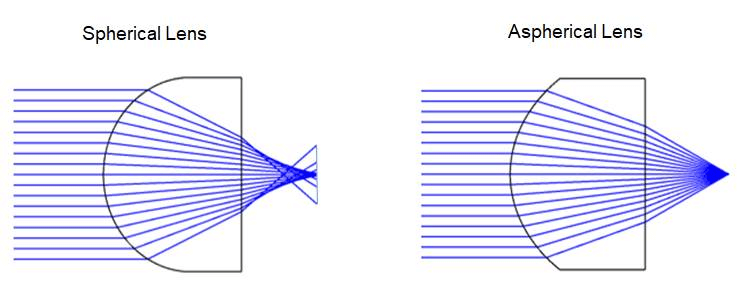

As the name suggests, an aspherical lens is a lens with a shape other than that of a regular sphere or cylinder. These lenses, which come in a variety of shapes, are used to correct spherical aberration and enhance image quality. Spherical aberration is a type of defect that occurs when light passes through a spherical surface. Depending on how close to the edge it enters the lens, light focuses at different distances, creating a blurry image. In comparison, aspheric lenses focus light to a single point, regardless of where the light ray enters, to reduce or entirely eliminate blurriness from the image.

In addition to reducing spherical aberration, aspherical lenses also correct other image distortions, such as astigmatism. Aspheric lenses have been used for many years to reduce spherical aberration and improve the performance of optical systems, but past high cost made them impossible to be used in real life applications in the past. Recent manufacturing advances in aspheric grinding and polishing have enabled subaperture polishing and produce high precision aspheres at affordable cost. A single one of the more affordable, high performance aspheric lenses can replace multiple spherical lenses result the same and sometimes better performance, leading to lighter weight, more compact and less complex systems at a cost-effective solution that is not possible years before. At Shanghai Optics, we design and manufacture standard and custom aspherical lenses to meet needs in a variety of industries. Read more about these innovative optical lenses below. Aspheres Manufacturing Tolerances

Precision aspherical lenses reduce visual defects and produce clearer images, making them ideal for many applications. Large aspheric lenses find use in telescopes and cameras, while smaller aspherical lenses perform essential functions in fiber optic networks, laser devices and surgical equipment. In almost any application, aspheric lenses provide users with the following benefits:

By reducing spherical aberration and focusing light to a single point, aspherical lenses produce clearer images, making them ideal for applications that require high precision, like focusing laser diodes.

Aspheric lenses allow optical engineers to increase the numeric aperture size of a lens without reducing image quality, which is perfect for applications that require high light throughput.

An aspheric lens can correct aberrations that would take multiple spherical lenses to correct. This capability means that a single aspheric lens can replace a complicated multi-lens system, leading to smaller, lighter, more efficient and less expensive assemblies.

In addition, because the surface shape of an aspheric lens is designed and formed to effectively reduce aberration in specific applications, custom aspheric lenses make flexible solutions to complex problems.

The optical engineers at Shanghai Optics showcase the manufacturing process of making the Aspheric Lens.

Like other kinds of optical lenses, aspheres can be produced in a number of ways. At Shanghai Optics, we use two main methods to produce custom aspheric lenses: molding and traditional polishing with the state-of-the-art manufacturing and metrology equipment. To mass produce aspheric lenses that require a lower level of precision, we use lens molding. In this method, we pour the heated lens material into custom molds, where they firm up and take their final shape. To ensure success, we make moldable aspheric lenses out of materials with low transformation temperatures, such as acrylic, plastic, BK-7, B270 and Pyrex. Molded aspheric lenses are the most cost-effective type of asphere. For large silicon aspheric lenses that require a higher level of precision, we turn to a traditional polishing method. With high-speed polishing equipment, we shape and refine precision aspheric lenses quickly while adhering to exact specifications. S.O. can manufacture lenses with best-fit-sphere deviation between a few millimeters and a few waves. Though the manufacturing process you choose will depend on your project requirements and the volume of lenses you require, you’ll find that our molded and polished lenses meet the highest expectations. Our production staff follows ISO 9001 standards and uses cutting-edge metrology equipment to take accurate and repeatable testing measurements.

Zinc Selenide Aspheric Lens – Diameter: 10mm / Thickness: 3mm

With a unique aspheric lens design to focus light to a single point, aspheric lenses offer higher precision and image quality compared to simple lenses. At Shanghai Optics, we have more than 55 years of experience providing high quality precision optical lenses to businesses around the world. Contact us for a quote, and request custom aspheric lenses from S.O. today.