Micro Optics

-

- Cylindrical Lenses

- Aspheric Lenses

- Achromatic Lenses

- Spherical Lenses

- Optical Prisms

- Optical Mirrors

- Beamsplitters

- Optical Windows

- Infrared Optics

- Micro Optics

- Optical Filters

- Colored Glass Filters

- Custom Shapes

- Laser Optics

- Freeform Optics

- Fresnel Lenses

- Light Pipe Homogenizing Rods

- TIR Lens

- Medical Device Optics

Micro optics are very small optical systems, typically ranging from a few micrometers to a millimeter in size. These systems include optical fibers with microscale core diameters, mini diffractive optical elements, micro optical mirrors, lenses, prisms, and lens arrays. Micro optics are generally defined as small optical components or systems with diameters between 1 micrometer to 1 millimeter.

At Shanghai Optics, we produce a wide range of custom micro optics and can collaborate with you to design and develop micro-optic lens assemblies tailored to your exact specifications. We utilize advanced manufacturing techniques, including photoresist reflow, micro contact printing, and direct laser writing technology, ensuring high precision and attention to detail in every component.

Applications of Micro Optics in Modern Optical Systems

Micro optics are key elements in many modern optical systems, and Shanghai Optics supplies these components to various industries. Aerospace, defense, materials processing, medical biophotonics, and industrial production all require micro-sized optics made to strict specifications.

These small optical components play a crucial role in remote sensing and embedded vision systems. In medical instrumentation, our micro optics are used for imaging, laser spectroscopy, endoscopy, and robotic surgery. The rise of high-quality cameras in mobile phones has also increased demand for tiny, precision lenses and durable windows that can withstand daily handling. Our specialty micro sapphire windows, for example, are now a standard feature in high-end smartphones.

Types of Micro Optics

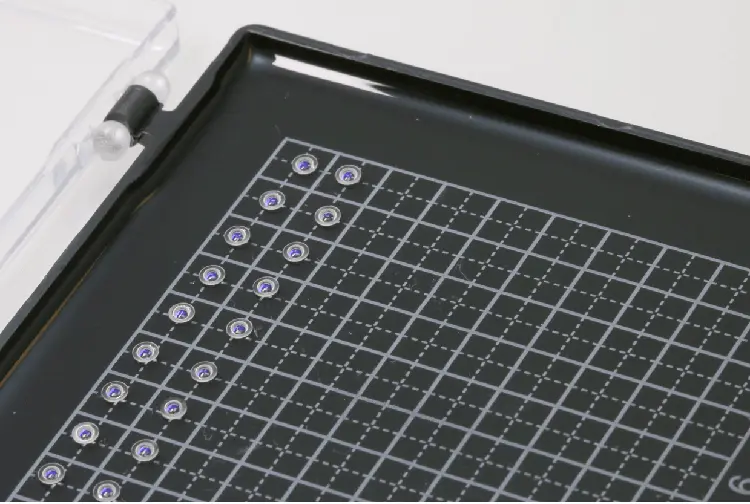

Beam Homogenization on a Micro Level: Microlens Arrays

Microlens arrays are typically used for beam homogenization and shaping. They can be paired with high-powered LEDs, lasers, and more. We offer square arrays in a standard 10 mm x 10 mm configuration and can customize them to the desired lens pitch and focal length. These arrays are often used in pairs and are ideal for fiber coupling, laser ablation, and welding.

Our fly’s eye condenser arrays are suitable for applications requiring short working distances and large illuminated fields. They are frequently chosen for medical lasers, fluorescence microscopy, and semiconductor instrumentation, as they transform non-uniform light into uniform irradiance distribution on the illumination plane.

These arrays need no adjustment and are constructed using a two-dimensional array of dual-surface cylindrical microlenses.

Micro Optics for Data Transfer: Fiber Optics

Fiber optics are long, thin strands of pure, high-quality glass. When arranged in bundles (optical cables), they can transmit light signals over long distances, allowing data to be processed at the speed of light.

Optical fibers consist of three parts: the core, the cladding, and a protective buffer coating. The core is a thin glass center that transmits light, surrounded by cladding with a higher refractive index to reflect light back into the core. This cladding is about ten times the diameter of the core. The outermost layer is a plastic buffer coating that protects the fiber.

Single-mode fibers, with cores around 8-10 microns in diameter, transmit light directly down the fiber in transverse mode and are used for telephone, cable TV, and internet signals. Multi-mode fibers, which have cores ranging from 50-100 microns, transmit infrared light and are suited for relaying data over shorter distances (under 600 meters) but are less efficient for longer distances due to modal dispersion. For instance, a 62.5/125 μm multimode fiber has a core diameter of 62.5 microns and a cladding diameter of 125 microns.

Special-purpose optical fibers can be designed with non-cylindrical cores or cladding. We also offer microspheres—tiny, perfectly formed spheres made from solid, fine annealed optical glass. These are used for relaying images in compact spaces or coupling light into or out of fibers. Their focal point is near the surface, making them ideal for use in close proximity with another sphere or microfiber, ensuring near-complete coupling.

Micro waveplates, used in fiber optics, modify the polarization state of light traveling through the fiber. We supply micro waveplates as small as 0.35mm x 0.35mm, with a thickness of 0.19 mm. These waveplates are made from crystal quartz and have a surface quality of 20/10 scratch-dig.

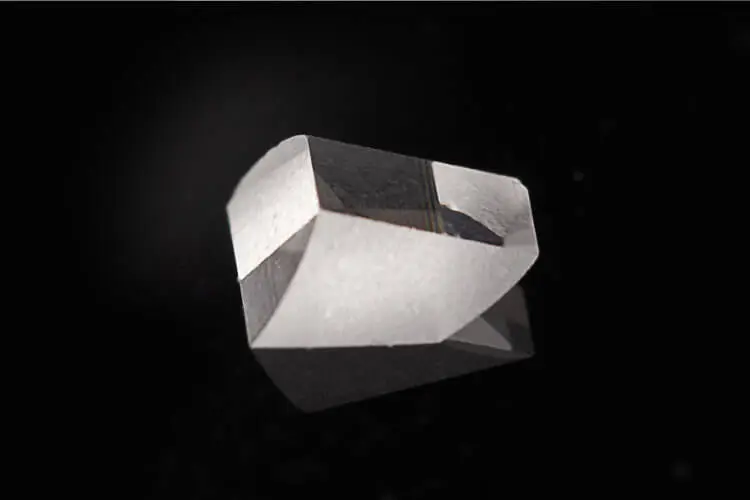

Micro Optics for Light Direction: Micro Prisms

Shanghai Optics also manufactures high-quality micro prisms. These prisms direct light from one optical channel to another and are suitable for fiber optic applications or use as circulators, interleavers, or MEMs. Their high reflectivity minimizes signal loss, and their precise engineering allows for exact light deviation.

We produce standard right-angle prisms, dove prisms, and penta prisms in micro sizes, and can also customize specialty prisms as needed. Right-angle micro prisms are typically used to reflect image paths or redirect light at a 90-degree angle. Dove prisms invert images, and penta prisms deviate light by 90 degrees without inversion.

Our micro polarization beamsplitter cubes (PBS) are used in fiber optics to split laser beams into their polarized components. These beam splitters are core components in polarizers and interleavers. We manufacture micro polarization beamsplitter cubes as small as 0.2 mm.

All of these micro optical components are subject to stringent quality checks, and we ensure that every micro prism leaving our factory meets quoted standards.

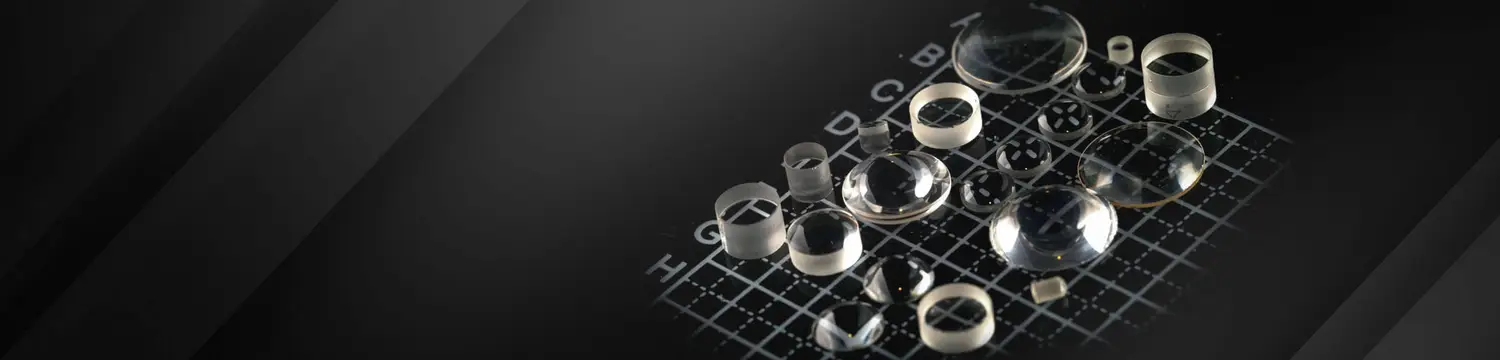

Microlenses For Complex Imaging

Our microlenses have a wide range of applications, including coupling light to optical fibers, increasing light collection in CCD arrays, and focusing light on active areas of LCDs for digital projectors. They are essential in compact imaging devices like photocopiers and smartphone cameras, as well as in 3D imaging and displays.

Shanghai Optics offers a variety of microlenses, including:

- Biconcave Microlens

- Plano Concave Microlens

- Biconvex Microlens

- Plano Convex Microlens

Each lens is precision-polished to a very high standard. As with all our micro components, they are subject to stringent quality control to meet tight specifications.

Need help?

We offer consultations and initial feasibility studies. If you have questions about limitations or lens capabilities we’re more than happy to work through your proposed custom components. As an unmatched custom optical provider, we’ll do everything that we can bring your vision to life.