Calcium Fluoride Lens

Calcium Fluoride Lens

-

- Cylindrical Lenses

- Aspheric Lenses

- Achromatic Lenses

- Spherical Lenses

- Optical Prisms

- Optical Mirrors

- Beamsplitters

- Optical Windows

- Infrared Optics

- Micro Optics

- Optical Filters

- Colored Glass Filters

- Custom Shapes

- Laser Optics

- Freeform Optics

- Fresnel Lenses

- Light Pipe Homogenizing Rods

- TIR Lens

- Medical Device Optics

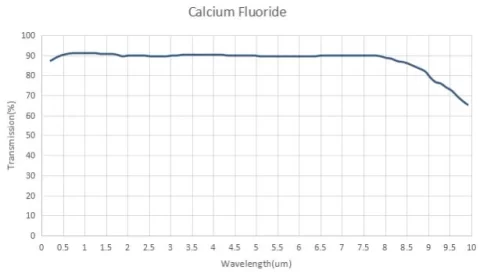

Calcium fluoride is often used in spectroscopic windows and lenses due to its high transmission from 350 nm to 7 µm. It is also commonly found in cryogenically cooled thermal imaging systems. Its low absorption and high damage threshold make it a popular choice for excimer laser optics. Calcium fluoride’s low refractive index allows it to be used without an antireflective coating. The Knoop hardness of calcium fluoride is 158.3.

Overview of Calcium Fluoride (CaF2) Lenses

Calcium fluoride (CaF2) lenses are highly valued for their excellent optical properties, making them ideal for a wide range of applications across the ultraviolet (UV) to infrared (IR) spectrum. CaF2 lenses offer high transmission between 180 nm and 8.0 μm, making them particularly useful in applications requiring high transmission, such as spectroscopy and thermal imaging.

Optical Characteristics

One of the key advantages of CaF2 lenses is their low refractive index, typically ranging from 1.35 to 1.51. This property reduces the need for anti-reflective (AR) coatings, although broadband AR coatings can further enhance performance. Spherical surfaces, including calcium fluoride plano-convex lenses, are designed to minimize spherical aberration, ensuring precise imaging and focusing capabilities across different focal lengths.

Laser and Thermal Imaging Applications

CaF2 lenses exhibit a high laser damage threshold, which is particularly advantageous in excimer laser applications where the lenses must withstand high-intensity light sources. Their low absorption and ability to handle IR wavelengths make them an excellent choice for light sources in both IR and UV spectrums. These characteristics offer superior performance in systems such as cryogenically cooled thermal imaging devices, excimer laser optics, and other applications demanding high durability and transmission efficiency.

While CaF2 lenses are a versatile choice for many optical applications, their suitability can vary depending on factors such as environmental conditions, system requirements, and the availability of alternative materials. For example, while CaF2 is generally resistant to environmental factors, extreme temperature fluctuations or exposure to certain chemicals may affect its performance. Additionally, other materials like zinc selenide (ZnSe) or germanium (Ge) may be more suitable for certain applications based on factors like cost, availability, or specific optical requirements.

Factory Standard

- Substrate Material: UV & IR Grade CaF2

- Shape: Spherical Plano-Concave, P-Convex, Concave-Convex or Aspheric

- Surface Figure: λ /4 at 633nm typical

- Surface Quality: 60-40 per MIL-PRF-13830B

- Dimensional Tolerance: + 0.00mm, – 0.1mm

- Thickness Tolerance: +/- 0.1mm

- Chamfer: 0.35mm at 45° typical

- Concentricity: 0.05mm

- Focal Length Tolerance: +/- 0.5% typical

- Antireflection Coating: User-specified, R<0.25% per surface

- Clear Aperture: Exceeds central 85% of dimension

- Damage Threshold: 5J/cm2, 20ns, 20Hz at 1064nm

Calcium fluoride lenses by Shanghai Optics

Shanghai Optics offers superior calcium fluoride lenses that are frequently used in applications where minimal distortion, high transmission, and the ability to work with a wide range of wavelengths are critical. Their exceptional performance makes them an excellent choice for high-precision optical systems. Contact us for information on manufacturing limits or custom specifications.

| IR GRADE | All measurements in mm | ||||||||

| Part Number | Nominal | Diameter | 800nm | 1064nm | 2940nm | 5000nm | Radius | ||

| F | D | F | F | F | F | R | TC | TE | |

| PLCX-25.4-20.6-CFIR | 50 | 25.4 | 47.8 | 48.1 | 49.3 | 51.6 | 20.6 | 7.4 | 3 |

| PLCX-25.4-31.4-CFIR | 75 | 25.4 | 72.9 | 73.2 | 75 | 78.6 | 31.4 | 5.7 | 3 |

| PLCX-25.4-41.9-CFIR | 100 | 25.4 | 97.3 | 97.8 | 100.1 | 105 | 41.9 | 5 | 3 |

| PLCX-38.1-41.9-CFIR | 100 | 38.1 | 97.3 | 97.8 | 100.1 | 105 | 41.9 | 8.6 | 4 |

| PLCX-25.4-62.7-CFIR | 150 | 25.4 | 145.7 | 146.4 | 150 | 157.2 | 62.7 | 4.3 | 3 |

| PLCX-25.4-83.8-CFIR | 200 | 25.4 | 194.7 | 195.7 | 200.5 | 210.2 | 83.8 | 4 | 3 |

| PLCX-25.4-104.0-CFIR | 250 | 25.4 | 241.6 | 242.7 | 248.7 | 260.7 | 104 | 3.8 | 3 |

| PLCX-25.4-210.0-CFIR | 500 | 25.4 | 487.8 | 490.1 | 502.1 | 526.4 | 210 | 3.4 | 3 |

| PLCX-25.4-417.7-CFIR | 1000 | 25.4 | 970.1 | 974.7 | 998.5 | 1046.9 | 417.7 | 3.2 | 3 |

| UV GRADE | All measurements in mm | ||||||||

| Part Number | Nominal | Diameter | 193nm | 212nm | 248nm | 308nm | Radius | ||

| F | D | F | F | F | F | R | TC | TE | |

| PLCX-12.7-11.9-CFUV | 25 | 12.7 | 23.6 | 24.4 | 25.3 | 23.2 | 11.9 | 3.8 | 2 |

| PLCX-25.4-23.6-CFUV | 50 | 25.4 | 47 | 48.5 | 50.4 | 52.1 | 23.6 | 6.7 | 3 |

| PLCX-25.4-35.0-CFUV | 75 | 25.4 | 69.8 | 72.1 | 74.8 | 77.3 | 35 | 5.4 | 3 |

| PLCX-25.4-46.4-CFUV | 100 | 25.4 | 92.5 | 95.6 | 99.1 | 102.5 | 46.4 | 4.8 | 3 |

| PLCX-38.1-46.4-CFUV | 100 | 38.1 | 92.5 | 95.6 | 99.1 | 102.5 | 46.4 | 8.1 | 4 |

| PLCX-25.4-70.6-CFUV | 150 | 25.4 | 140.8 | 145.4 | 150.9 | 156 | 70.6 | 4.2 | 3 |

| PLCX-50.8-70.6-CFUV | 150 | 50.8 | 140.8 | 145.4 | 150.9 | 156 | 70.6 | 9.7 | 5 |

| PLCX-50.8-93.2-CFUV | 200 | 50.8 | 185.9 | 192 | 199.2 | 206 | 93.2 | 8.6 | 5 |

| PLCX-25.4-118.0-CFUV | 250 | 25.4 | 235.2 | 243 | 252.1 | 206.7 | 118 | 3.7 | 3 |

| PLCX-25.4.231.8-CFUV | 500 | 25.4 | 462.2 | 477.4 | 495.3 | 512.2 | 231.8 | 3.3 | 3 |

| PLCX-50.8-231.8-CFUV | 500 | 50.8 | 462.2 | 477.4 | 495.3 | 512.2 | 231.8 | 6.4 | 5 |

| PLCX-25.4-469.5-CFUV | 1000 | 25.4 | 936.2 | 966.9 | 1003.2 | 1037.5 | 469.5 | 3.2 | 3 |

| PLCX-50.8-469.5-CFUV | 1000 | 50.8 | 936.2 | 966.9 | 1003.2 | 1037.5 | 469.5 | 5.7 | 5 |

Need help?

We offer consultations and initial feasibility studies. If you have questions about limitations or lens capabilities we’re more than happy to work through your proposed custom components. As an unmatched custom optical provider, we’ll do everything that we can bring your vision to life.