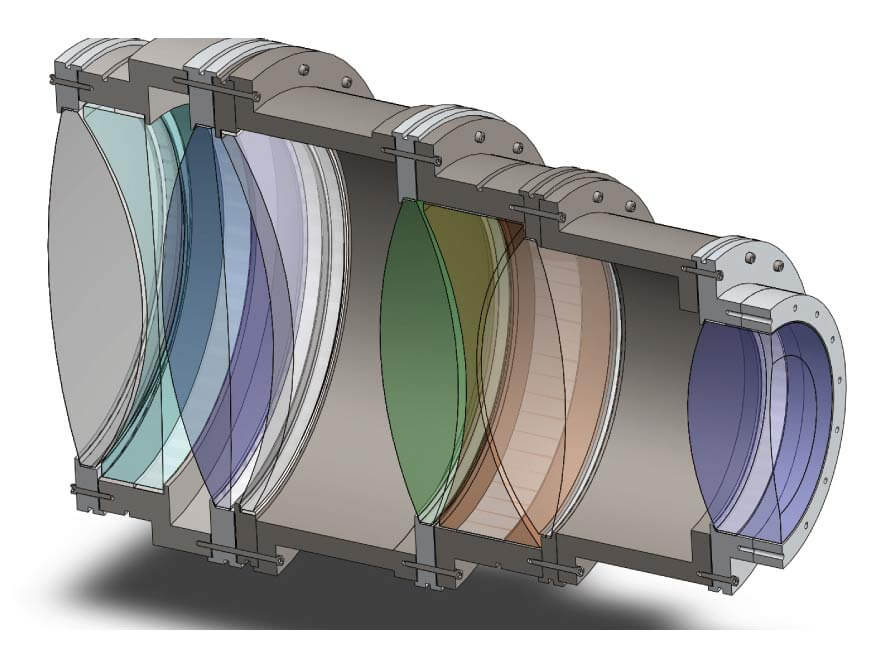

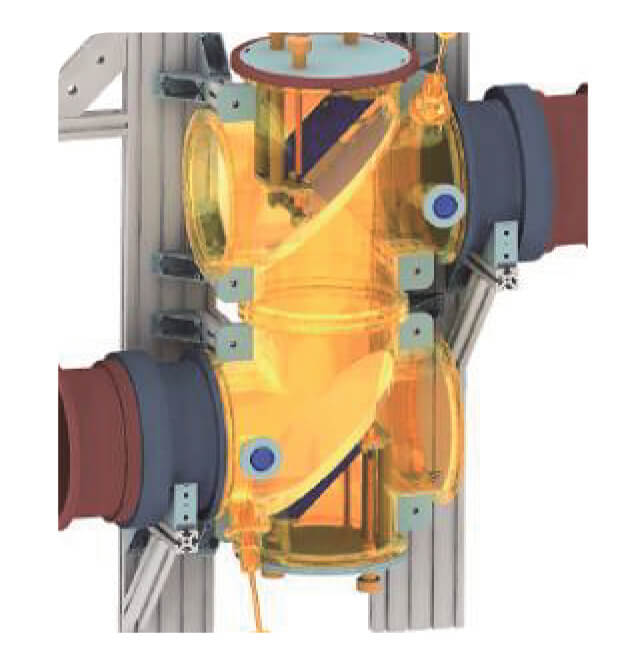

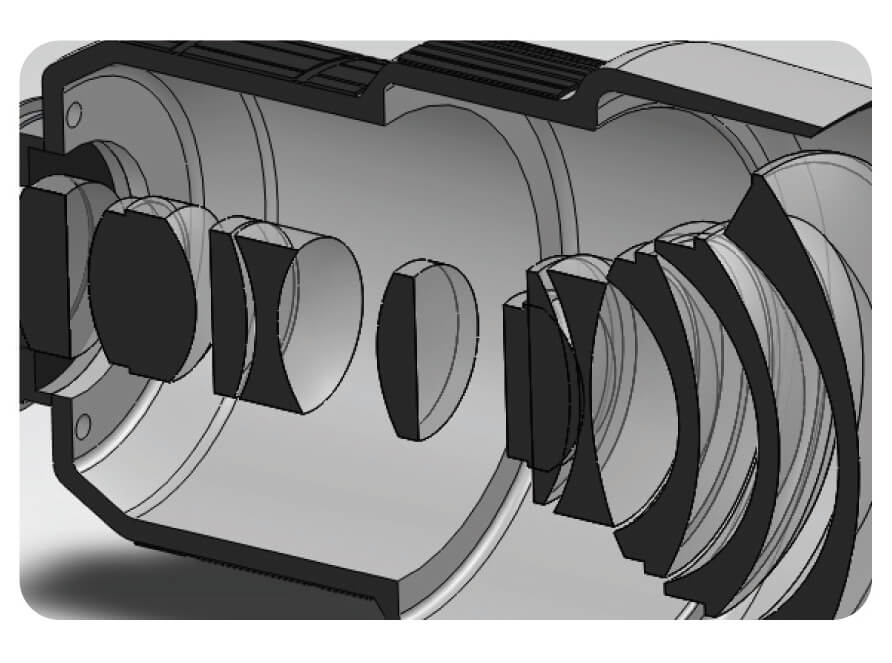

Design of the optimum lens barrel is much more than just providing a holder for the lens elements. An optomechanical engineer is responsible for taking into account all factors of mounting a lens system that may introduce stress and strain at component level thus degrade image quality. Every manufacturing process has problems that threaten to become black holes for development time and money that can use up resources and do serious damage to your delivery schedule and budget. Shanghai Optics put 55 years of specialized design and engineering experience to work to help you steer clear of production black holes.

Our custom design services and streamlined production methods help us design production processes that consistently deliver resulted in:

Members of our closely integrated design and production teams use their specialized skills and experience to create customized optical instruments, assemblies, and optical systems. We design and execute plans from initial concept and prototyping to final product manufacture. And, we create each optomechanical design by:

Our engineers’ experience with high-precision optics and real-life use cases can help you deliver products that cost less effective without sacrificing the end results.

Our tightly integrated teams of optical design and mechanical engineers use:

We follow these design practices and MIL standards. The results: high-precision optical instruments that are durable,conform to specs and perform consistently, no matter how large the production run.

Optics are just part of optical instrument design. Engineers must select materials such as metals for their weight, durability, cost, and stability in the finished product. Choosing the right metal for components is an important part of optomechanical design. We provide components made of a wide variety of metals, which include:

Discover how our optomechanical design services can cut the time, effort, and costs of building high-precision optical lens/assembly. Call our sales engineers today at 732-321-6915 or contact us at rfq@shanghai-optics.com. Or visit Build our own lens to start your design process today!