Optical Metrology

Optical Metrology Overview

Optical metrology uses light to establish measurement standards. More broadly, it’s the science of measurement using light. This encompasses both the study of light’s properties and the use of light to measure characteristics like temperature, dimensions, and distance in other objects.

Shanghai Optics leverages state-of-the-art optical metrology equipment to produce and rigorously test precision optical components and systems. We inspect and qualify all manufactured parts, ensuring they meet our customers’ specific requirements and MIL/SPEC standards. All parts are shipped with comprehensive documentation, including inspection reports, material certificates, and coating curves (if applicable).

Our advanced in-house metrology equipment empowers us to test components for compliance with various international measurement standards, encompassing all critical stages of the optical production process.

We are committed to fulfilling our customers’ requirements from the very beginning, starting with the procurement of raw materials. All orders are meticulously controlled and monitored in adherence to ISO 9001 standards, from the incoming inspection of purchased materials to the final step in the production process. This ensures that every product leaving our facility meets the highest quality standards.

Benefits of Optical Metrology

Optical metrology offers the potential for exceptional precision, limited only by quantum or laser noise that could hinder detection. Typically, optical measurements are rapid, making optical metrology ideal for in-process inspections. Optical measurements are non-contact, making them among the least destructive measurement techniques available. This makes it suitable even for the most sensitive items or components, and it is an integral part of quality control in our factory.

Optical Metrology in Action: Selected Examples

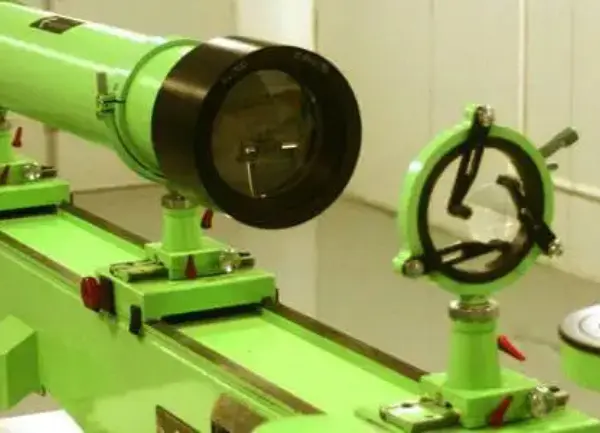

Measuring with Lasers

Various optical metrology methods exist, each suited to different measurement scales and requirements. These methods include time-of-flight measurements, triangulation, phase shift methods, and interferometry.

In time-of-flight measurements, a short laser pulse is emitted, and the time it takes for a portion of the pulse to be reflected is measured. The distance is calculated as half the round-trip time multiplied by the speed of light. This method is typically employed for long distances, and its accuracy is limited by the precision of time measurement: every 1 nanosecond deviation results in a spatial inaccuracy of 15 centimeters.

Optical Clocks

Optical clocks are based on ultra-precise measurements of optical frequencies, and are both more stable and more accurate than the atomic clocks which are widely used as the standard in time measurement. In fact, they are now being used to recalibrate standard atomic clocks against drifting. They are based on multi-TH electromagnetic oscillations, in contrast to cesium atomic clocks which rely on a transition at 9192631770 Hz. This allows optical clocks to outperform atomic clocks by a very large margin; often by multiple orders of magnitude.

Optical Temperature Sensors

Optical temperature sensors typically use fiber optics to measure the temperature of an object or environment. These sensors are widely used in industry, for routine measurement as well as for disaster prevention. For instance, they may be used to protect against uncontrolled fires. The benefits of these sensors are that they don’t use electrical cables, are insensitive to electromagnetic interference, and are suited to a wide range of temperatures.

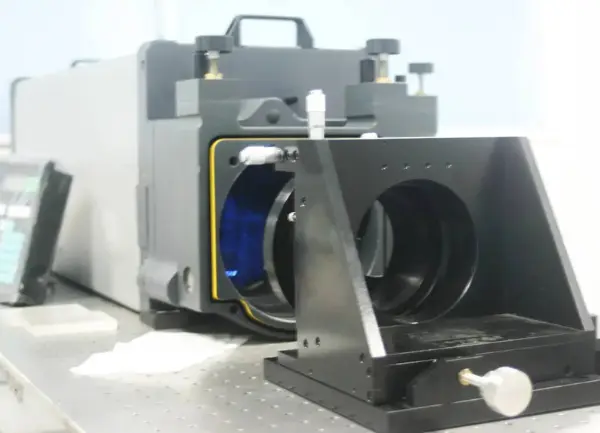

Optical Profilometers

An optical profilometer employs light to measure surface profiles. These instruments are non-contact and deliver more accurate profiling than traditional methods like ordinary microscopes. High-resolution optical profilometers are frequently used to inspect the surface of optical components such as prisms, glass flats, and laser mirrors. They are indispensable tools for surface analysis and quality control in our manufacturing processes. Furthermore, they are utilized in semiconductor chip inspection and the production of certain mechanical parts where a high-quality surface finish is critical. Optical profilometers encompass various technologies, including interferometers, interferometer microscopes, confocal scanning microscopes, focus variation microscopes, digital holographic microscopes, and triangulation sensors.

[Lens Assembly and Metrology]

A exclusive look into our custom lens product and assembly process

Optical Metrology at Shanghai Optics

Optical metrology is the science and technology of using light sources to measure the properties of objects in real time. Techniques include laser interferometry and time-of-flight measurements, utilizing interference patterns for precise, non-contact measurements in quality control and production processes.

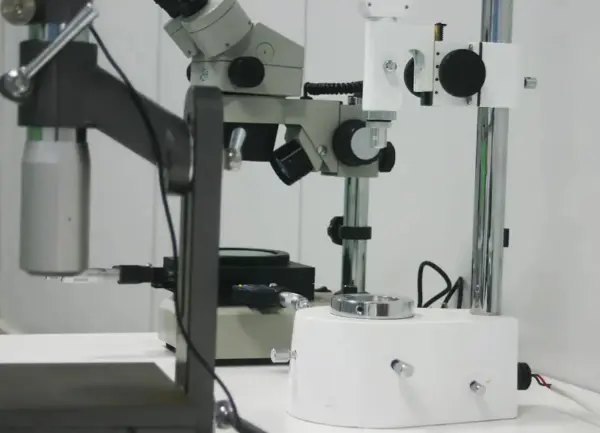

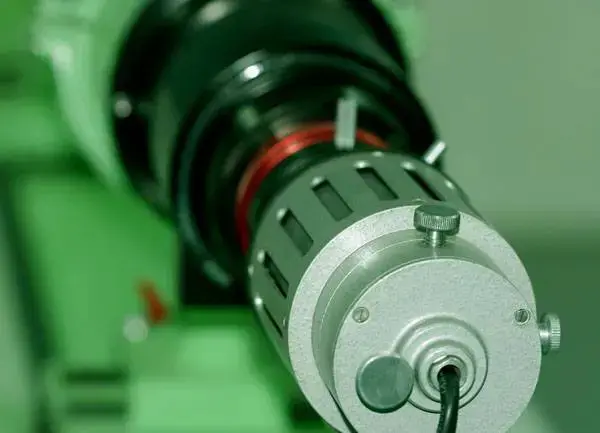

At Shanghai Optics, we utilize cutting-edge optical metrology to ensure that every optical component that leaves our factory fully meets all applicable standards and is optimized for its intended application. Our advanced equipment includes coordinate measurement machines (CMMs), spectrophotometers, profilometers, and interferometers.

We procure all raw materials, including glass, metal, polishing materials, adhesives, etc., in strict accordance with the customer’s original prints or specifications.

We have established operating procedures to ensure complete traceability of the raw material batches used or to be used in our optical products.

As a leading manufacturer of custom lenses and high-precision optical assemblies with over 55 years of experience, we fully understand the significance of metrology in optical manufacturing. Our pursuit of ever-higher measurement accuracy drives us to continually invest in optical test equipment and expand our capabilities in optical metrology.

Surface quality and flatness of each optical component are tightly controlled. We also conduct extensive in-house optical and environmental testing to guarantee our components will perform as expected, even under challenging conditions such as temperature fluctuations, shock, vibration, or humidity. Optical measurements enable us to verify that each of our wide range of components meets advertised specifications, allowing us to stand confidently behind our products.

We also provide the optical components necessary for your own in-house optical metrology needs. Our design experts are eager to collaborate with you to design and implement the most suitable metrology solutions for your industry or application.

Need help?

We offer consultations and initial feasibility studies. If you have questions about limitations or lens capabilities we’re more than happy to work through your proposed custom components. As an unmatched custom optical provider, we’ll do everything that we can bring your vision to life.