-

- Cylindrical Lenses

- Aspheric Lenses

- Achromatic Lenses

- Spherical Lenses

- Optical Prisms

- Optical Mirrors

- Beamsplitters

- Optical Windows

- Infrared Optics

- Micro Optics

- Optical Filters

- Colored Glass Filters

- Custom Shapes

- Laser Optics

- Freeform Optics

- Fresnel Lenses

- Light Pipe Homogenizing Rods

- TIR Lens

- Medical Device Optics

Understanding Powell Lenses

Powell lenses are laser line generator lens that can fan out collimated beams in one dimension. They have the shape of a prism with a rounded roof, and are often used to transform a narrow laser beam into a uniformly illuminating line. While a cylindrical lens produces a poorly illuminated line with fading edges and a hot spot at the center, the straight lines produced by Powell lenses have an even distribution of energy and an even distribution of light along the line.

This even distribution is caused, surprisingly enough, by the rounded roof that characterizes the Powell lens. This two dimensional aspheric curve introduces a large spherical aberration into the system, and this spherical aberration is involved decreasing the light in the central area while increasing the light intensity at the edge. Thus instead of the non uniform Gaussian laser beam that would be produced by cylindrical lenses a uniform straight line is generated. Although there are other ways to perform uniform laser illumination, Powell lenses are by far the most powerful and flexible way to achieve this.

Powell lenses were discovered in 1986 by Dr. Ian Powell, at the National Research Council of Canada in Ottawa, Ontario. They are currently widely used in both industrial and research applications in settings where a uniform intensity distribution is essential, either because the laser light serves as an illumination source or, for instance in materials processing, when the entire area illuminated by the laser must be processed in a uniform, equatable manner.

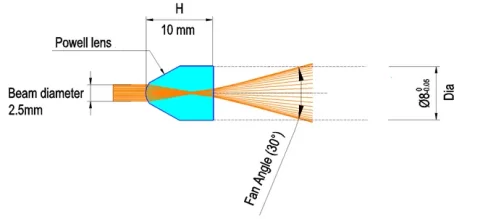

30° Fan Angle Laser Line Generator Lens

Selecting a Powell Lens from Shanghai Optics

At Shanghai Optics, we produce high quality Powell lenses designed for all manner of machine vision applications, from automobile assembly and food manufacturing to bio-medical applications. Our careful quality control ensures that all parameters of your lens fall within tight specifications, and will perform consistently in industrial conditions.

The fan angle of your Powell lens is determined by the index of refraction of the substrate used and the roof angle of the lens. It describes how wide an angle the laser beam is fanned out over.

A Powell lens is limited by the line used as input, and it is important to select a lens designed for the laser beam width you intend to use. If a Powell lens optimized for a specific laser width is used for a narrower laser, the resulting line will display fading at the ends. If a Powell lens is used for a wider laser line, the resulting line will display increased intensity toward the ends.

Custom Powell Lenses from Shanghai Optics

Powell Lenses Specifications

| Material | N-BK7, N-SF57, N-SF2 |

| Diameter | 9mm |

| Diameter Tolerance | +0.00/-0.06mm |

| Fan Angle | 10°, 20°, 30°, 35°, 45°, 54°, 55°, 70°, 75°, 80°, 90°, 110° |

| Fan Angle Tolerance | +/- 1° |

| Wavelength Range | 405nm-808nm |

| Input Beam diameter | 0.5mm, 0.8mm, 1mm, 2mm, 4mm, 5mm, or other |

| Surface Irregularity | λ/4@632nm |

| Surface Quality (Scratch/Dig) | 80/50, 60/40 |

| Line Uniformity | 10% variation over central 80% of line at 632nm |

| Line Straightness | 0.1% over central 80% of line at 632nm |

| AR Coating Range | As per customer’s request |

We are open to discuss custom options that might be a closer fit to your application. Our team of engineers would be happy to work with you to determine the Powell lens that best fits your needs, and our state of the art factory and over 50 years of optical manufacturing experience ensures that we can both design or produce the optics that perform best for your application. Contact us for a quote, and request a custom Powell Lenses from S.O. today.