Case Study: F-Theta Lens Revolution in Laser Optics

Case Study: F-Theta Lens Revolution in Laser Optics

This case study delves into a groundbreaking project centered around the development of an F-theta lens that challenges traditional configurations. The primary objective is to fulfill unique customer requirements, prompting a systematic refinement and upgrade process to enhance performance, particularly in laser applications.

Overview

The focal point of this project is optimizing performance for low-energy lasers through the utilization of a quartz design. This design capitalizes on the unique attributes of the material, deviating significantly from the conventional telecentric lens approach. Importantly, this departure has been effectively communicated and accepted by the customer without objections.

Precision is paramount in meeting customer specifications, particularly in working and flange distances as depicted in the structural diagram. The lens’s distinctive design, featuring a large middle lens and two smaller side lenses, requires the use of an essential lens base for optimal alignment during assembly. Careful adjustment of the third lens in subsequent stages ensures compliance with stringent performance standards.

Precision Challenges and Innovative Solutions

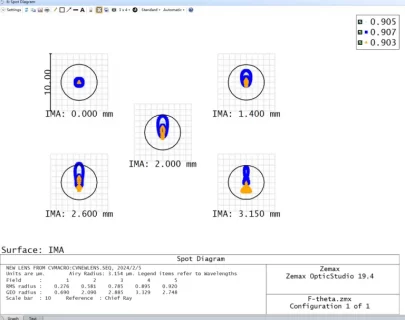

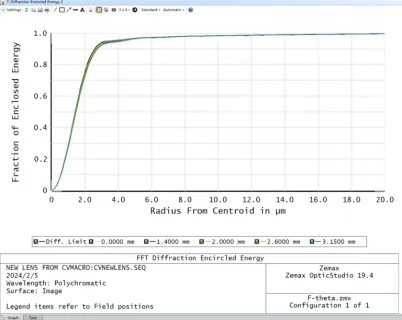

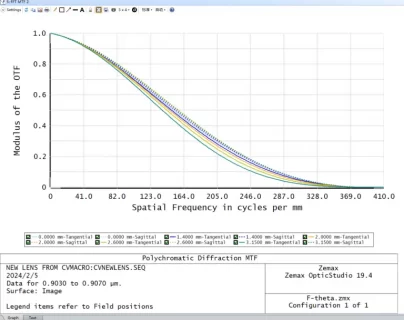

The critical focus of the F-theta lens is the accurate convergence of the spot size on the image surface. Spot quality assessment employs the Modulation Transfer Function (MTF), aligning with established measurement techniques. Challenges in evaluating spot quality arise due to the designed wavelength potentially exceeding the existing equipment’s test range, limited to a maximum of 950nm. To address this, a compensatory measure involves post-focusing, ensuring compatibility with testing needs.

Comprehensive testing is facilitated by procuring 900nm and 1050nm filters, as the existing 950nm filter proves too broad for precise test requirements. This strategic approach accommodates the lens design and provides insights into the company’s equipment capabilities.

This case study showcases a transformative departure from traditional F-theta lens designs, emphasizing the strategic integration of a compensating element to meet customer demands for an expanded field of view. Meticulous enhancements, utilizing a quartz design and departing from conventional approaches, underscore the dedication to meeting stringent performance standards. Despite challenges in evaluating spot quality, the shift to the Modulation Transfer Function reflects adaptability and a commitment to excellence in optical innovation.

Do not hesitate to contact Shanghai Optics today. We’d be more than happy to discuss your projects and how best they can become a success.