Plano Concave Lenses

-

- Cylindrical Lenses

- Aspheric Lenses

- Achromatic Lenses

- Spherical Lenses

- Optical Prisms

- Optical Mirrors

- Beamsplitters

- Optical Windows

- Infrared Optics

- Micro Optics

- Optical Filters

- Colored Glass Filters

- Custom Shapes

- Laser Optics

- Freeform Optics

- Fresnel Lenses

- Light Pipe Homogenizing Rods

- TIR Lens

- Medical Device Optics

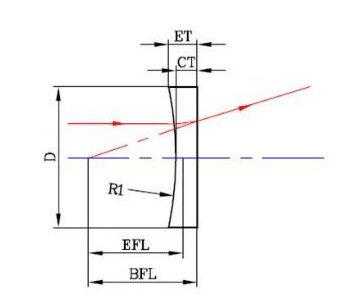

A plano-concave lens is an optical lens with one concave surface and one flat surface. It has a negative focal length and is commonly used in light projection, beam expansion, or to increase the focal length of an optical system. Plano-concave lenses are essential in applications where a virtual image is required or when working with distant objects. They are often paired with convex lenses to form complete optical systems, utilizing the principles of the lens formula to achieve the desired results.

Shanghai Optics manufactures a wide variety of plano concave lenses optimized for the UV (ultraviolet), visible, and IR (infrared) spectrums. Our range includes options with AR coatings for enhanced performance. We also offer custom optical lenses, including bi concave lenses and double concave lenses, ideal for applications requiring light divergence or image formation from distant objects.

Our facility produces lenses ranging from 2.33 mm to 1000 mm in diameter, with both coated and uncoated options. Our design engineers can collaborate with you to develop custom convex and concave lenses tailored to your specific needs. Whether you’re looking to work with a convex lens or need specialized designs for your optical systems, we are equipped to meet your requirements.

Factory Standard

- Shape: Plano-Concave

- Diameter Tolerance: ± 0.05mm

- Thickness Tolerance: ± 0.05mm

- Radius:± 0.3%

- Focal Length Tolerance: ± 1%

- Surface Quality: 40-20 Scratch-Dig(After Coating)

- Surface Flatness: λ/4 @633 nm

- Centration: < 3 arc minutes

- Clear Aperture: > 95% of central dimension

Specifications of our lenses include material, surface quality, clear aperture, diameter tolerance, thickness tolerance, and surface irregularity.

Contact us for manufacturing limit or custom specifications.

Plano-Concave Lenses Capabilities

| Specifications | Factory Standards | Manufacturing Limit |

| Dimension Tolerance | +/-0.05mm | +/-0.01mm |

| Center Thickness Tolerance | +/-0.05 mm | +/-0.01mm |

| Radius Tolerance | +/-0.3% | +/-0.1% |

| Surface Quality(S/D) | 40-20 | 10-5 |

| Irregularity | 1/4 Lambda | < 1/10 Lambda |

| Centration(arc min) | 3′ | 1′ |