Infrared Optics

Infrared Optics

-

- Cylindrical Lenses

- Aspheric Lenses

- Achromatic Lenses

- Spherical Lenses

- Optical Prisms

- Optical Mirrors

- Beamsplitters

- Optical Windows

- Infrared Optics

- Micro Optics

- Optical Filters

- Colored Glass Filters

- Custom Shapes

- Laser Optics

- Freeform Optics

- Fresnel Lenses

- Light Pipe Homogenizing Rods

- TIR Lens

- Medical Device Optics

At Shanghai Optics we produce a wide range of quality infrared optics, including infrared lenses, prisms, windows, mirrors, and laser and imaging assemblies. Our state of the art equipment allows us to achieve unparalleled precision and surface quality, and every piece we manufacture is subject to stringent quality controls.

Our diamond turning machines enable us to produce sub-nanometer level surface finishes and form accuracies to the sub-micrometer. Each diamond-turned IR optical component is manufactured individually, and can be customized to your exact form specifications for IR Optics applications.

Our diamond fly cutting machine allows us to generate precision diffraction gratings and other linear elements on optical elements with contoured diamond shapes.

We offer a wide range of IR substrates, including Ge, Si, ZnSe, ZnS, ZnS , CaF2, BaF2, GaAs, and Chalcogenide. Our IR Optics are available with multiple anti-reflection coating options that can increase durability and improve performance. Our selection of optical materials includes high-quality options such as germanium, silicon, zinc selenide, calcium fluoride, barium fluoride, gallium arsenide, and chalcogenide glasses. These materials are chosen for their excellent transmission properties across various wavelengths in the infrared spectrum, as well as their thermal and mechanical properties which are crucial for specific applications.

Infrared Optics Applications

Infrared optics have applications in a many fields, from high power CO2 lasers, which work at 10.6 μm, to night-vision thermal imaging cameras (MWIR and LWIR bands) and IR imaging. They are also important in spectroscopy, as the transitions used in identifying many trace gases are in the mid infrared region. We produce laser line optics as well as infrared components which perform well over a wide wavelength range, and our experienced team can provide full design support and consultation.

Selecting Infrared Optics for Your Application

The infrared region, between 0.750 and 1000μm (750 – 1000000nm) is often divided into three sub regions: the near infrared, or NIR, between 0.750 and 3μm, the mid-wave infrared (MWIR), between 3 and 30μm, and the long wave infrared (LWIR) from 30 to 1000μm. Your choice of substrate and anti-reflection coating will depend on which wavelength requires prime transmittance in your application. For instance, if you are transmitting visible light in the MWIR, germanium may be a good choice. For NIR applications, sapphire may be ideal.

Other specifications you may want to consider in your choice of infrared optics include thermal properties and index of refraction.

The thermal properties of a substrate quantify how it reacts to heat. Often, infrared optical elements will be exposed to widely varying temperatures. Some IR applications also produce a large amount of heat. To determine whether an IR substrate is suitable for your application you will want to check the index gradient and coefficient of thermal expansion (CTE). If a given substrate has a high index gradient, it may have suboptimal optical performance when used in a thermally volatile setting. If it has a high CTE, it may expand or contract at a high rate given a large change in temperature.

The materials most often used in infrared optics vary widely in index of refraction. Germanium, for instance, has an index of refraction of 4.0003, compared with 1.413 for MgF. The availability of substrates with this wide range of index of refraction gives added flexibility in system design.

The dispersion of an IR material measures the change in index of wavelength with respect to wavelength as well as the chromatic aberration, or the separation of wavelength. Dispersion is quantified, inversely, with the Abbe number, which is defined as ratio of the the refractive index at the d wavelength minus 1, over the difference between the index of refraction at the f and c lines. If a substrate has an Abbe number of greater than 55, it is less dispersive and we call it a crown material. More dispersive substrates with Abbe numbers of lower than 55 are called flint materials.

Optical IR Substrates

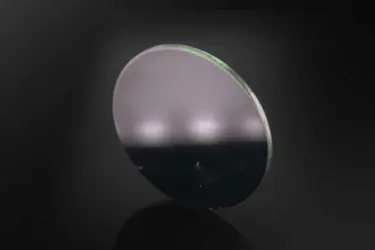

Germanium Ge is a good choice for optical lenses, windows, and prisms, and it performs well without infrared anti-reflection coatings. It transmits from 2 to 13µm. The high Knoop Hardness (780) makes it ideal for applications where durability is key, but it can only be used at temperatures below 100°C.

Barium fluoride BaF2 is often used for IR spectroscopy, as its properties include wide broadband transmission and a low index of refraction (1.48). BaF2 can remain stable up to 800°C, but is resistant to thermal shock and should be used in a dry environment. Knoop Hardness is 82.

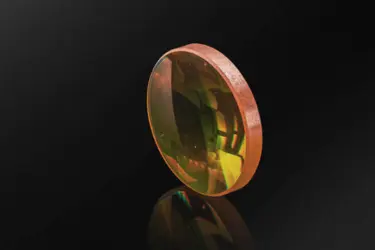

Zinc Selenide ZnSe infrared optics have a high resistance to thermal shock, which makes them a good choice for thermal imaging cameras, systems, and CO2 laser systems. The index of refraction nd is 2.403. ZnSe optics are not as durable as other options and we do not recommend them for optical systems in harsh environments.

Magnesium Flouride MgF2 is more rugged and durable than ZnSe, and offers very good transmission from 120nm to 7μm. The index of refraction, at 1.413, is the lowest index of refraction for commonly used IR substrates. MgF has a density of 3.11 g/cm3, a Knoop hardness of 415, and is resistant to both chemical etching and laser damage.

Gallium Arsenide GaAs optical components transmit over 40% between 2µm to 15µm and are very hard and dense. A Knoop Hardness of 750 makes them comparable to Germanium optics, but the index of refraction is slightly lower at 3.3. Our GaAs lenses and windows are coated with a broadband antireflective optical coating to improve performance.

IR grade fused Silica has a reduced amount of OH- ions as compared to other grades of Silica, and this provides a higher transmission in NIR wavelength ranges. Fused silica offers consistent, repeatable performance and a low thermal expansion coefficient. IR material is more expensive to produce than UV-grade fused Silica but is still more budget-friendly than other options.

Chalcogenide is an amorphous glass and is easier to work with than conventional IR crystalline materials. It is quickly becoming a top choice among IR materials for optical engineers and lens designers. Chalcogenide glass is an ideal material for both high-performance infrared imaging systems and high-volume commercial applications. A number of different chemical composition choices exist for ChG, but BD6, composed of arsenic and selenium (As 40 Se 60), represents the best choice from a cost and ease-of-manufacturing perspective. Chalcogenide infrared glass materials and lenses are an excellent alternative in some applications for the more expensive and commodity price-driven materials such as Ge, ZnSe and ZnS2. Chalcogenide glasses transmit primarily in the midwave-infrared (MWIR) and LWIR wavebands, making them suitable for thermal imaging applications.

Sapphire, a crystalline form of aluminum oxide (Al2O3), is widely used in infrared optics. It offers excellent transmission in both near-infrared (NIR) and mid-infrared (MIR) regions, from 0.14μm to 6μm, with a refractive index of 1.768. Its precise fabrication enables the creation of high-quality lenses, windows, and prisms, ensuring accurate infrared imaging and focusing.

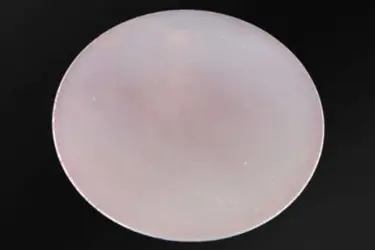

Calcium Fluoride (CaF2) is known for its exceptional transparency, spanning from 0.13μm to 12μm, and boasting a refractive index of 1.434. Its transmission efficiency typically exceeds 90% for wavelengths in the MIR and FIR regions. Additionally, CaF2 demonstrates outstanding thermal stability, preserving its optical properties across a broad temperature range.

Chemical Vapor Deposition Zinc Sulfide (CVD ZnS) provides a cost-effective solution for infrared windows and optical elements. With a refractive index of 2.371, it offers transmittance from 1μm to 13μm. However, its softness requires careful handling and protective coatings to enhance durability.

Multispectral Zinc Sulfide (M-ZnS) is a specialized zinc sulfide material engineered for enhanced transmission properties from 0.25μm to 13μm, boasting a refractive index of 2.368. It is particularly well-suited for high-performance common aperture systems requiring effective operation across a broad spectrum of wavelengths.

Silicon (Si) is widely utilized in optics for its high transmission (1.1μm to 9μm), thermal stability, and durability against scratches, making it suitable for various applications, including those involving high temperatures.

Custom Infrared Optics

We are able to customize Infrared (IR) Optics such as IR lenses, windows, filters, and other optical components to meet the requirements of your application, and our design team can work with you as you go from prototype stage to production. Our wide range of choice in substrates and optical coatings, coupled with state of the art machinery and metrology lab, ensure that your device will be fitted with the highest quality optics.

Need help?

We offer consultations and initial feasibility studies. If you have questions about limitations or lens capabilities we’re more than happy to work through your proposed custom components. As an unmatched custom optical provider, we’ll do everything that we can bring your vision to life.