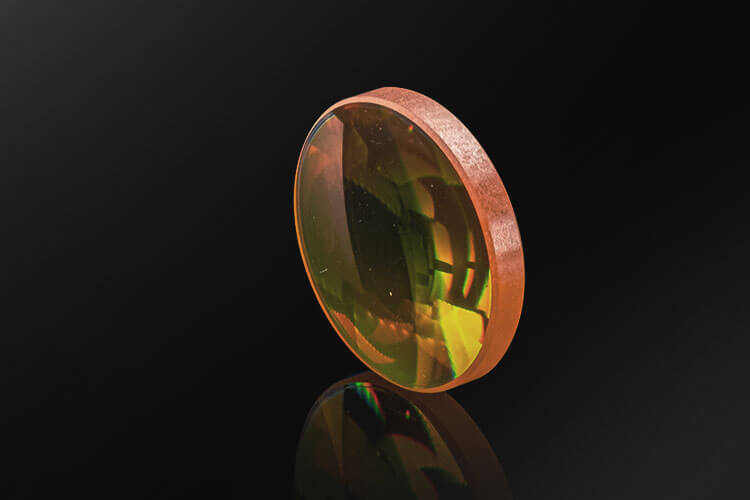

ZnSe Window

ZnSe Window

-

- Cylindrical Lenses

- Aspheric Lenses

- Achromatic Lenses

- Spherical Lenses

- Optical Prisms

- Optical Mirrors

- Beamsplitters

- Optical Windows

- Infrared Optics

- Micro Optics

- Optical Filters

- Colored Glass Filters

- Custom Shapes

- Laser Optics

- Freeform Optics

- Fresnel Lenses

- Light Pipe Homogenizing Rods

- TIR Lens

- Medical Device Optics

A ZnSe window is an optical window formed of Zinc Selenide, a transparent, highly stable material. These windows feature extremely low IR absorption, and have a high resistance to thermal shock. Their transmission range is 0.5 μm – 22 μm.

ZnSe optical windows are often used in Forward Looking Infrared (FLIR) and thermal imaging systems, and they can be used as resonator windows in high power CO2 laser systems at 10.6 microns. Zinc Selenide has a low dispersion and low absorption coefficient, and a density of 5.27 g/cm3. Its refractive index is near 2.4. It is non-hygroscopic, which means it won’t absorb moisture from the air.

The Zinc Selenide ZnSe used in our windows is produced by a process called Chemical Vapor Deposition (CVD). This enables us to achieve the extreme purity needed for high powered optics: 99.999% purity. During the process, zinc vapor and H2Se gas react to form sheets of ZnSe on graphite susceptors. These polycrystalline ZnSe plates are then precisely tooled to form optical windows.

Zinc Selenide optical windows must be handled with extreme care due to the materials softness: the Knoop number of ZnSe is 105. These optical components are not suitable for harsh environment. This same softness, however, makes them resilient to thermal shock. They can withstand thermally demanding environments and are chemically stable. This gives them importance in many applications including medical, industrial, and defense imaging.

Handling and Cleaning of ZnSe Windows

Because of the softness of the material, you should only handle a Zinc Selenide window by its edges. Apply uniform pressure to avoid warping. The utmost caution should be used while cleaning ZnSe optics to avoid scratching the soft surface. Dust or lint particles can typically be blown off with a dust free blower or air bulb. If further cleaning is needed, acetone or isopropyl alcohol may be used to clean the surface. While holding the optic by its edges, gently wipe the surface with a damp cotton ball. Do not rub, and do not exert pressure. Use only surgical-quality cotton balls.

Zinc Selenide is toxic, and protective rubber gloves should be used whenever handling windows or lenses made of this substrate.

Shanghai Optics Factory Standards for ZnSe Windows

Our factory is subject to very high quality controls, and Zinc Selenide optics produced are carefully inspected to ensure it meets all standards. Our factory standard ensures a clear aperture of more than 85 %. Wavefront distortion is required to be no more than l/4 per 25mm.

Shanghai Optics windows are available in a variety of different sizes and thicknesses. Diameter tolerance is defined as no more than +0.0, -0.05mm, and thickness tolerance no more than +/- 0.1mm. Both AR coated and noncoated options are available for Zinc Selenide windows.

Our design team is experienced in working with clients in a wide variety of fields, and we would be happy to help you design the optical system that works best for your situation. Please contact us to discuss your custom specifications.

Factory Standard

- Material: ZnSe

- Irregularity (fringe): l/4

- Diameter Tolerance: +0.0, -0.05mm

- Thickness Tolerance: +/- 0.1mm

- Clear Aperture: >85%

- Parallelism: 5 arc min

- Surface Quality: 40-20

- Wavefront Distortion: l/4 per 25mm

Contact us for manufacturing limit or custom specifications.

Need help?

We offer consultations and initial feasibility studies. If you have questions about limitations or lens capabilities we’re more than happy to work through your proposed custom components. As an unmatched custom optical provider, we’ll do everything that we can bring your vision to life.