Metalized Sapphire Windows

Metalized Sapphire Windows

-

- Cylindrical Lenses

- Aspheric Lenses

- Achromatic Lenses

- Spherical Lenses

- Optical Prisms

- Optical Mirrors

- Beamsplitters

- Optical Windows

- Infrared Optics

- Micro Optics

- Optical Filters

- Colored Glass Filters

- Custom Shapes

- Laser Optics

- Freeform Optics

- Fresnel Lenses

- Light Pipe Homogenizing Rods

- TIR Lens

- Medical Device Optics

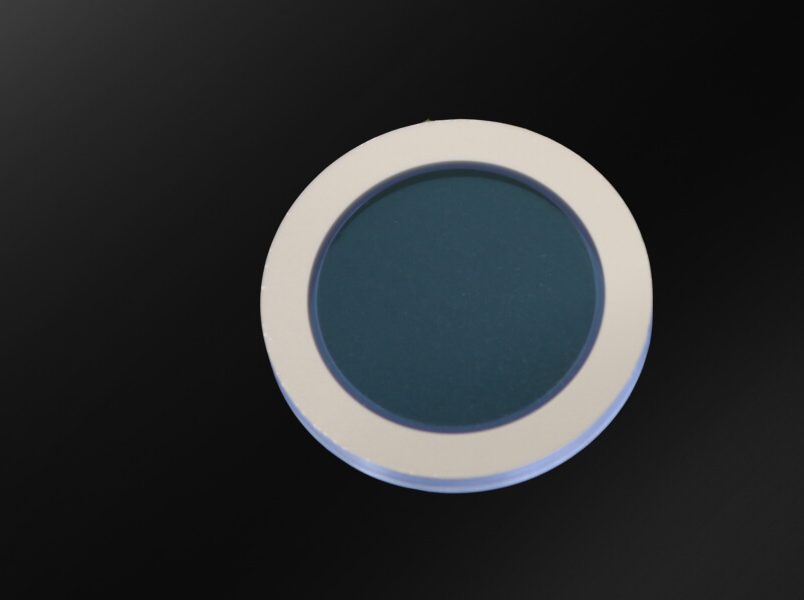

Metallized Sapphire Windows

Metallized sapphire windows feature metallized edge surfaces which allow the windows to be soldered or bonded directly into an opto-electronic assembly, creating a hermetic seal. Since sapphire windows can better withstand harsh environments, these metallized windows are especially useful for chemical and plasma sanitation applications. They also are important in a wide variety of other optical assemblies, including infrared imaging and medical devices. Our solderable sapphire windows are produced by applying thin layers of gold compounds around the edges of the window, and meet MIL-STD-883 solderability standards.

To learn how S.O. could assist with your current optics project, request a quote online or contact one of our friendly representatives for more information.

Metallized Sapphire Windows Manufacturing Capability

| Substrate Material: | Sapphire |

| Dimension: | Ф2.5mm x 0.28 mm, Ф2.9mm x 0.28mm or customer requirement |

| Center Spectrum: | 1270 ~ 1650nm or customer requirement |

| Metallization: | CrNiAu/TiNiAu/TiPtAu or customer requirement, Au80Sn20 Solder Coating optional |

| Surface Quality: | 20/10 (MIL-PRF-13830B) |