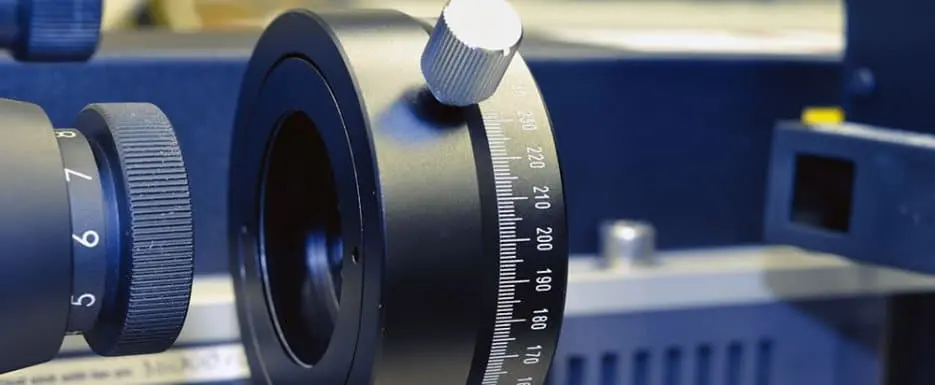

Opto-Mechanical Design

An opto-mechanical engineer does more than just provide a holder or mount for optical components. Improper mounting can cause stresses or distortions on component surfaces, degrading system performance under operating environment conditions. With over 60 years of experience in designing and manufacturing opto-mechanical products, Shanghai Optics offers cost-effective solutions and fast delivery services. Our Optomechanical engineering design experience and streamlined production methods enable us to create highly efficient design and production processes. Compared to other optical manufacturers, we offer:

- Cost-effective solutions.

- A 20% faster time to delivery for research and engineering projects.

- A 20% to 30% faster time to market for manufactured products.

A Detailed Understanding of Optical Applications

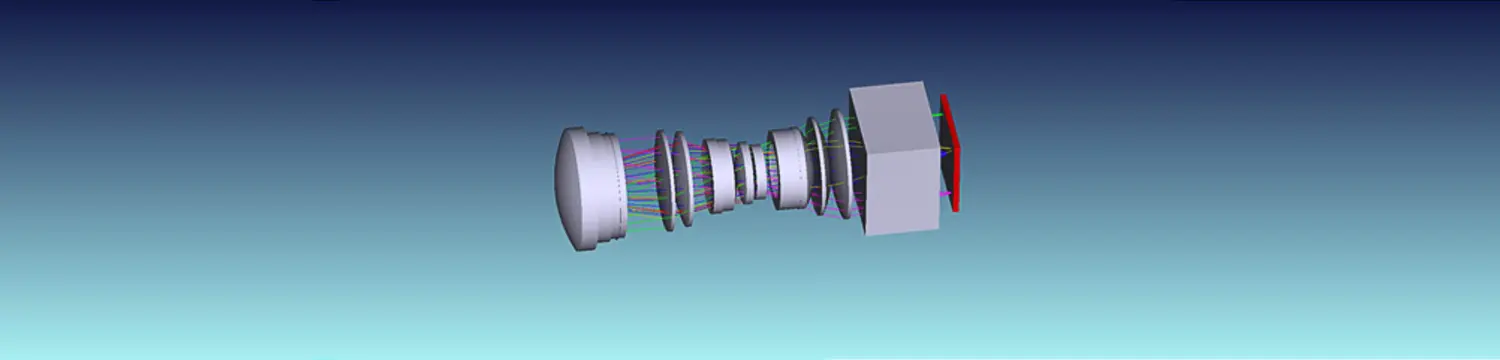

Members of our closely integrated design and production teams use their specialized skills and experience to create customized optical instruments, assemblies, and optical systems. They design and execute plans from initial concept and prototyping to final product manufacture. Each opto-mechanical design is created by:

- Performing a detailed analysis at the initial RFQ stage.

- Studying the challenges of building custom optical instruments.

- Considering and estimating the effects of environmental factors (stress, shock, temperature, vibration, and work environment) on the instrument.

- Meticulously choosing materials to avoid functional failures due to deflections of opto-mechanical systems

- Applying optimization practices from the earliest design stage to final production.

Our experience in designing high-precision optical instruments can help you quickly deliver high-quality products at a lower cost.

Designing for Durability, Consistent Quality, and Lower Costs

Our tightly integrated teams of optical design and mechanical engineers employ the following techniques:

- Use Individual component mounting methods to maximize system stability.

- Employ kinematic design and analysis to overcome opto-mechanical constraints within the instrument.

- Choose Achrotherm glass and select appropriate housing materials during the design stage to minimize the impact of temperature fluctuations, employing passive compensation schemes to achieve heat-resistant designs.

- Employ vibration control techniques to minimize the sensitivity of optical components to external disturbances.

- Utilize advanced adhesives and bonding techniques to reduce the instruments’ weight and volume, resulting in a compact streamlined design.

By adhering to these design practices and MIL standards, we produce high-precision optical instruments that are both durable and cost-effective, consistently delivering exceptional performance.

Softwares

Choosing Metals for Strength, Stability and Support

For mechanical parts (housings, spacers, retainers, etc.), engineers must carefully select materials, such as metals, considering factors like weight, durability, cost, and stability. Selecting the appropriate material or metal is crucial for ensuring the optimal performance of both the mechanical and optical components within opto-mechanical systems.

We offer mechanical components crafted from a diverse selection of metals, including:

- Aluminum alloy: Widely used in various brands and types of optical mechanical components. We also offer components with a black-oxidized surface treatment for enhanced durability and aesthetics.

- Copper: Utilized for its excellent thermal conductivity, as well as in screws and other components requiring abrasion resistance.

- Indium steel: Chosen for its exceptional thermal stability.

- Stainless steel: Extensively used for structural components, especially in vacuum instrument design and manufacturing. We exercise meticulous care when processing small, threaded-diameter lens barrels to ensure precision and quality.

- Titanium: Valued for its high stability and light weight, titanium finds application in numerous high-end optical systems, even though it presents challenges in processing.

Discover how our opto-mechanical design services can help you save time, effort, and costs when building high-precision optical lenses and assemblies. Contact our sales engineers today at 732-321-6915 or email us at rfq@shanghai-optics.com. Or visit “Build Your Own Lens” to start your design process today!

Need help?

We offer consultations and initial feasibility studies. If you have questions about limitations or lens capabilities we’re more than happy to work through your proposed custom components. As an unmatched custom optical provider, we’ll do everything that we can bring your vision to life.

Related Content

Coating Design

Optical Components